Low-voltage switchgear products are integral in managing electrical control, protection, and distribution across various sectors. They operate under 1,000 volts AC and adhere to standards like IEC 61439 and ANSI C37 for reliability and safety. Options include modular assemblies, customized configurations, and digital integrations to enhance performance. Leaders like Conya offer advanced offerings with industry partnerships for improved system solutions. Exploring further reveals thorough insights into ideal product selection and deployment.

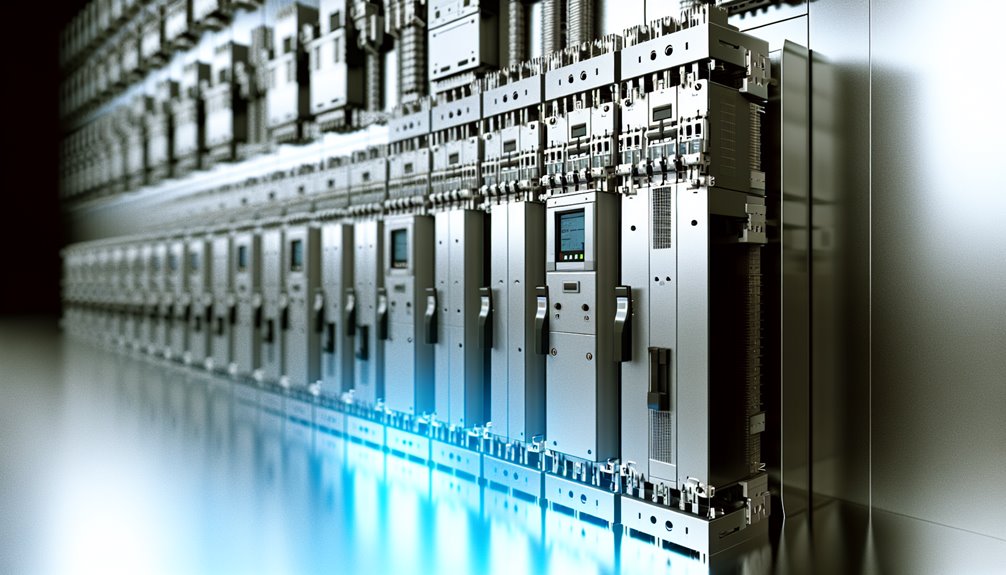

Low voltage switchgear products are electrical distribution systems designed to control, protect, and isolate circuits operating at voltages up to 1,000 volts. These systems form the backbone of safe, reliable, and efficient power distribution in industrial facilities, commercial buildings, and critical infrastructure.

At their core, low voltage switchgear integrates circuit breakers, fuses, busbars, relays, meters, and control units within a robust enclosure to manage electrical loads and prevent faults. By quickly disconnecting faulty circuits, they protect equipment, reduce downtime, and ensure personnel safety.

There are several types of LV switchgear, each suited to different operational requirements:

Understanding these core functions helps ensure that the selected low voltage switchgear products deliver reliability, safety, and efficiency for any electrical system.

Selecting the right low voltage switchgear products requires careful consideration of technical specifications to ensure safety, reliability, and long-term performance. The key parameters include:

| Specification | Typical Range / Feature |

|---|---|

| Rated Voltage | Up to 690–1,000 V |

| Rated Current | 400–4,000 A |

| Short-Circuit Withstand | 25–80 kA |

| Enclosure Protection | IP30–IP54 |

| Structural Form | Fixed / Withdrawable / Modular |

| Monitoring | Optional digital/IoT integration |

By evaluating these specifications, facilities can choose low voltage switchgear products that align with operational requirements, safety standards, and future expansion needs.

Conya's portfolio of low voltage switchgear products includes the XL-21 Power Distribution Cabinet, designed for efficient power management and distribution.

The GGJ Low Voltage Reactive Power Intelligent Compensation Device offers advanced solutions for power factor correction, enhancing system efficiency.

Additionally, the range features GGD Low Voltage Complete Switchgear, MNS Low Voltage Withdrawable Switchgear, and GCK Low Voltage Withdrawable Switchgear, each engineered for flexibility and modularity in power distribution systems.

The XL-21 Power Distribution Cabinet serves as an essential component in three-phase low-voltage systems, specifically designed for applications requiring an AC voltage capacity of up to 500 volts. This cabinet is ideal for power plants and industrial mining enterprises, ensuring efficient power distribution. Key XL 21 features include its stringent installation guidelines, which necessitate indoor placement against a wall with front maintenance access. Benefits of the XL-21 include optimized performance within ambient temperatures ranging from -5°C to +40°C and an installation altitude limit of 2000 meters.

| Parameter | Specifications |

|---|---|

| Voltage Capacity | Up to 500 volts |

| Installation | Indoor, against the wall |

| Temperature Range | -5°C to +40°C |

| Humidity Tolerance | 50% at +40°C, 90% at +20°C |

| Altitude Limit | Up to 2,000 meters |

Following the discussion on the XL-21 Power Distribution Cabinet, attention now shifts to the GGJ Low Voltage Reactive Power Intelligent Compensation Device, a standout product within the Conya Low Voltage Switchgear lineup.

This device employs CAD and microcomputer control to provide intelligent compensation, effectively tracking and managing reactive power. It is specifically engineered for low-voltage power grids, designed to enhance the power factor to 0.9 or above, and minimize reactive power loss.

The system supports transformers ranging from 130-600kVA, ensuring adaptability across various configurations. Its robust protection mechanisms include overvoltage, subharmonic, and overcompensation safeguards, alongside superior anti-interference capabilities.

The device's data management features secure parameter integrity, even during outages, offering seamless operational continuity and heightened system reliability.

GGD Low Voltage Complete Switchgear stands as an essential component within low-voltage distribution systems, engineered to operate in AC 50Hz environments. Designed for applications up to 380V and 5000A, it is pivotal in power plants, substations, and industrial sectors. The ggd switchgear features high breaking capacity, dynamic stability, and a flexible electrical scheme. Its robust construction guarantees superior performance, as outlined by IEC439 and GB7251 standards. Adhering to ggd installation guidelines, it mandates an indoor setting with controlled environmental conditions, avoiding excessive vibrations or corrosive elements. The installation should not exceed a 5% inclination relative to the vertical plane.

| Feature / Parameter | Specification | Typical Application |

|---|---|---|

| Rated Voltage | 380 V | Power conversion |

| Rated Current | 5,000 A | Power distribution |

| Installation Environment | Indoor, free from severe vibration or impact | Industrial plants, mining enterprises |

| Altitude Limit | Up to 2,000 m | Substations |

MNS low-voltage withdrawable switchgear, a pinnacle of engineering excellence, represents a sophisticated advancement in electrical distribution systems, particularly within China.

Developed referencing ABB's MNS series, it exemplifies precision in modular design, facilitating flexibility and customization. The standardized modular series with drawers guarantees MNS advantages, such as enhanced configuration versatility.

Operating at AC 50 (60) Hz with a rated voltage of 400V or 660V, and current capacity up to 5000A, it complies with GB7251.1 and IEC60439 standards, assuring robust reliability.

Its mechanical interlocking devices greatly bolster safety, essential for controlling power generation, transmission, and distribution.

The switchgear is integral in diverse settings, including power plants, industrial enterprises, and communication centers, demonstrating its pivotal role in modern electrical infrastructure.

Building upon the sophisticated engineering exemplified by the MNS low-voltage withdrawable switchgear, the GCK Low Voltage Withdrawable Switchgear from Conya represents an advanced, modular solution tailored for power distribution and motor control applications.

GCK features include a modular, reliable design that guarantees seamless integration with AC three-phase four-wire or five-wire systems, operating at 380V or 660V with a frequency of 50Hz. Rated currents up to 5000A enable stable performance in demanding environments.

GCK applications span power plants, metallurgy, petrochemicals, textiles, and commercial buildings, providing centralized motor control and guaranteeing operational efficiency.

Compliance with GB7251.1-2005 and IEC60439.1-1992 standards, alongside CCC approval, affirms its quality and reliability, making it an indispensable component for modern industrial and commercial infrastructure.

The Xeergy Eaton Authorized Low-Voltage Switchgear, a product line under Conya Low Voltage Switchgear Products, stands as a paragon of engineering precision and reliability in low-voltage power distribution.

Utilizing cutting-edge Eaton technology, this switchgear is designed to meet the rigorous GB7251 standard, offering a maximum current range of 6300A. Its innovative features guarantee peak performance across diverse application fields such as power systems, data centers, industrial and mining enterprises, petrochemicals, and commercial infrastructure.

Certified with national mandatory testing and third-party type testing, the Xeergy series undergoes thorough verification, including temperature rise, short circuit withstand, and dielectric performance.

Manufactured with ISO9000 and ISO14000 certifications, it incorporates high-quality Eaton components, assuring superior system operation and control.

Among the advanced offerings in the Conya Low Voltage Switchgear Products, MDmax® stands as an ABB Authorized Digital Low-Voltage Switchgear, exemplifying a convergence of digital technology and robust engineering.

This product achieves superior digital integration, enhancing operational management and energy efficiency. MDmax® is engineered in compliance with the GB7251 standard, ensuring high performance and reliability across various application fields such as power systems, data centers, and industrial enterprises.

It boasts a maximum current capacity of 6300A and is backed by thorough third-party type testing, including temperature rise and short circuit withstand verifications.

Leveraging high-quality components, MDmax® guarantees excellent functionality and aligns with ISO9000 and ISO14000 certifications, delivering a reliable, efficient solution for modern electrical infrastructure demands.

Adhering to stringent safety standards and obtaining relevant certifications is essential for guaranteeing the reliability and safety of LV switchgear systems.

Safety regulations such as IEC 61439 and ANSI C37 establish criteria for design, construction, and performance. Compliance with these regulations is verified through rigorous certification processes, which include type testing and routine testing.

These processes guarantee that switchgear products can withstand electrical, thermal, and mechanical stresses during operation. Certification bodies like UL and CE mark conformity with applicable standards, providing assurance of product safety and quality.

Additionally, manufacturers must maintain thorough documentation and traceability throughout the product lifecycle. This disciplined approach enables facility operators to have confidence in the operational integrity and safety of their electrical infrastructure.

Offering a multitude of custom design and configuration options allows low voltage switchgear products to meet the specific needs of diverse applications.

Custom configurations enhance operational efficiency by tailoring switchgear systems to specific load requirements and spatial constraints. This design flexibility enables integration with existing infrastructure and compatibility with varied electrical systems.

Users benefit from precise control over components such as circuit breakers, busbar systems, and protective relays, ensuring peak performance and safety. Design flexibility facilitates scalability, accommodating future expansions without significant overhauls.

Additionally, custom configurations provide opportunities to incorporate advanced monitoring and automation features, aligning with modern technological advancements. Consequently, these tailored solutions support energy management strategies and promote sustainable operations, delivering a robust solution tailored to user-specific demands.

Longevity characterizes the lifecycle advantages of low voltage switchgear products, underscoring their cost-effectiveness. These systems are engineered for durability, providing extended operational periods with minimal maintenance intervention.

The lifecycle benefits stem from robust construction materials and advanced design methodologies that enhance reliability and reduce failure rates. Moreover, the modular nature of low voltage switchgear allows for seamless upgrades, ensuring compliance with evolving standards without necessitating complete replacement.

Cost savings are realized through reduced downtime and lower maintenance costs. By minimizing disruptions, organizations can achieve higher productivity levels, directly impacting financial performance.

In addition, the initial investment in high-quality switchgear is offset by the extended service life, resulting in a favorable total cost of ownership over time. Such strategic advantages underscore their value in complex electrical systems.

Low voltage switchgear products are essential across a wide range of industrial, commercial, and infrastructure environments. Their ability to safely manage electrical distribution and protect equipment makes them a core component in critical operations.

Switchgear ensures stable power distribution for machinery, automation systems, and production lines. Modular and intelligent configurations allow plants to expand or reconfigure electrical networks as production demands evolve.

High-reliability LV switchgear protects sensitive equipment, maintains uptime, and supports efficient load management. Digital monitoring enables rapid fault detection and energy optimization in complex facilities.

From conventional power stations to renewable energy systems, switchgear manages variable loads, integrates with energy storage units, and ensures safe distribution of generated power.

Switchgear is used in transportation hubs, hospitals, and government facilities to ensure uninterrupted power supply and compliance with safety regulations.

Selecting a reliable supplier is essential to ensure that low voltage switchgear products meet performance, safety, and operational requirements. The first consideration is compliance and certification. Switchgear should adhere to recognized standards such as IEC 61439, GB 7251, and ISO certifications, guaranteeing safety, reliability, and regulatory compatibility.

Equally important is the supplier’s technical expertise and ability to provide tailored solutions. High-quality suppliers can configure modular designs, intelligent monitoring, and custom layouts to match the unique needs of your facility, ensuring seamless integration with existing systems.

Quality assurance and testing are critical for consistent performance. Products should undergo rigorous manufacturing inspections, routine tests, and type tests to minimize the risk of failure over the system’s lifecycle.

Finally, consider the supplier’s after-sales support, spare parts availability, and project experience. Timely delivery, responsive technical assistance, and a proven track record in similar installations help maintain efficiency, reduce downtime, and provide long-term operational confidence.

Low voltage switchgear products are evolving rapidly to meet the demands of modern power systems. Intelligent and digital switchgear integrates real-time monitoring, remote diagnostics, and predictive maintenance capabilities. These features allow facilities to identify potential issues before they lead to downtime, optimize load management, and improve overall operational efficiency.

Sustainability is another key trend. Advanced switchgear designs focus on energy efficiency, reduced losses, and environmentally friendly materials, helping facilities minimize their carbon footprint while maintaining high performance. Modular and compact configurations also reduce material use and installation space, supporting more sustainable infrastructure planning.

The convergence of smart technology and sustainability enables facilities to achieve both operational excellence and energy optimization. Selecting switchgear with these capabilities ensures a future-ready electrical distribution system that adapts to changing energy demands while supporting long-term efficiency and safety.

Conya delivers low voltage switchgear products engineered for reliability, safety, and operational efficiency across diverse industries. With decades of experience in design and manufacturing, Conya combines robust engineering, modular flexibility, and advanced intelligent features to meet the requirements of modern power distribution systems.

All products are manufactured in compliance with IEC 61439, GB 7251, and relevant international standards, ensuring consistent performance and regulatory alignment. Conya also partners with globally recognized technology providers such as ABB and Eaton, integrating authorized components to enhance system reliability and digital functionality.

Beyond product quality, Conya provides comprehensive technical support, customizable solutions, and responsive after-sales service, helping facilities optimize installation, maintenance, and system operation. Whether for industrial plants, commercial complexes, or critical infrastructure, Conya’s switchgear solutions are designed to deliver long-term value, operational safety, and energy efficiency.

Time travel to the present, low voltage switchgear optimizes energy savings and enhances load management by precisely controlling electrical distribution. This meticulous regulation minimizes energy waste, ensuring effective power utilization, appealing to those demanding precise energy efficiency and control.

Preventive maintenance for low voltage switchgear necessitates routine inspections, ensuring ideal performance and safety. Key tasks include thermal imaging, electrical testing, cleaning, and verifying connections, which collectively mitigate risks of equipment failure and extend operational life.

The harmonious incorporation of low voltage switchgear into pre-existing systems often encounters integration challenges. Ensuring system compatibility necessitates meticulous analysis, addressing interoperability concerns, and aligning technical specifications to maintain operational efficacy and control within the electrical infrastructure.

Common issues with low voltage switchgear include insulation failures, contact wear, and temperature fluctuations. Troubleshooting techniques involve thermal imaging, regular maintenance checks, and predictive diagnostics to identify potential failures and enhance system reliability and performance.

Seamlessly weaving renewable integration into existing infrastructures, low voltage switchgear acts as a linchpin for effective energy management. Through precise load distribution and real-time monitoring, it enhances efficiency, ensuring ideal utilization of renewable energy sources within controlled environments.

Choosing the right low voltage switchgear products is critical for ensuring safe, reliable, and efficient power distribution across industrial, commercial, and infrastructure facilities. High-quality switchgear protects equipment, minimizes downtime, and supports long-term operational efficiency.

Conya offers a comprehensive range of switchgear solutions, from XL-21 power distribution cabinets and GGD complete switchgear to intelligent MDmax® digital systems, all designed to meet international standards and modern energy management needs. With modular flexibility, advanced monitoring, and proven reliability, Conya products provide both immediate performance benefits and long-term value.

Explore Conya’s Low Voltage Switchgear Series to find the right solution for your facility or contact our team for a tailored consultation.