High voltage switchgear manufacturers such as ABB, Siemens, GE Vernova, and Mitsubishi Electric are integral to power distribution systems, offering critical equipment like gas-insulated and air-insulated switchgear. Certified manufacturers ascertain safety, compliance, and enhanced reliability, aligning with standards like IEC 62271 and ANSI/IEEE C37. Choosing a reputable manufacturer involves evaluating quality, innovation, and support services. Insight into top players and their market presence provides strategic advantage and informs smart purchasing decisions. Discover their role shaping future power infrastructure.

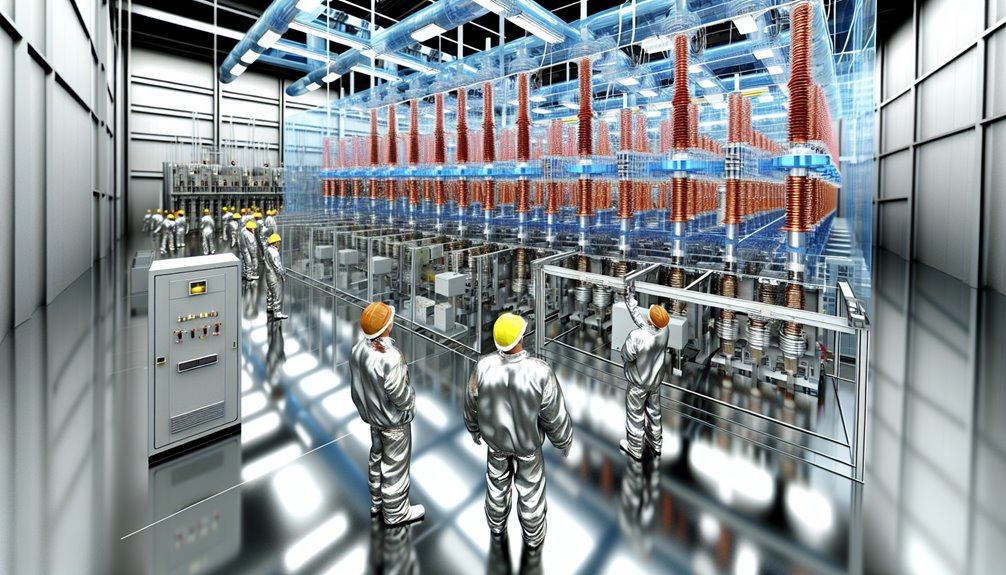

High voltage switchgear, an integral component of electrical power systems, serves the primary function of ensuring uninterrupted power distribution across complex networks. It is utilized to control, protect, and isolate electrical circuits while maintaining system integrity.

High voltage switchgear is rated above 36 kV AC and is classified into gas-insulated indoor-type or air-insulated outdoor-type, depending on environmental and operational specifications. These products are essential for minimizing downtime and enhancing the overall reliability of power systems.

High voltage switchgear manufacturers and high voltage switchgear companies provide solutions that include fuses, switches, relays, isolators, and circuit breakers. By facilitating efficient power transmission at high voltages, they reduce current, enhance safety, and optimize energy management across expansive infrastructure.

Selecting a certified switchgear manufacturer is pivotal to ensuring safety, reliability, and compliance with essential standards such as IEC 62271, ANSI/IEEE C37, ISO 9001, CE, and UL.

These certifications signify adherence to rigorous quality control processes and industry regulations, which are indispensable for minimizing lifecycle costs despite potentially higher initial pricing.

The integration of certified systems not only safeguards operational integrity but also aligns with best practices for regulatory compliance and long-term sustainability.

When considering the complexities of electrical systems, partnering with a certified switchgear manufacturer is essential to guarantee safety, reliability, and compliance with regulatory standards.

Certified manufacturers, particularly those offering sf6-free switchgear solutions, adhere to rigorous industry benchmarks, such as IEC 62271 certified switchgear, ensuring peak performance and environmental responsibility. This adherence minimizes electrical hazards and enhances operational stability.

Reliability is further assured through extensive testing protocols and advanced design methodologies, reducing the likelihood of system failures and unplanned outages.

Regulatory compliance streamlines approval processes and mitigates potential legal and financial risks associated with non-compliance.

Understanding the dichotomy between lifecycle costs and initial pricing is essential when considering switchgear investments. High voltage switchgear manufacturers provide critical components for industrial power distribution systems, where initial pricing may not always reflect the total cost of ownership.

An analytical assessment reveals that while initial costs can be attractive, long-term expenses, including maintenance, repair, and potential downtime, must be factored into decision-making. Partnering with a certified manufacturer guarantees quality and reliability, reducing unexpected costs over the switchgear's lifespan.

The focus on lifecycle costs highlights the importance of thorough evaluations beyond upfront pricing. Manufacturers offering robust products and support contribute to reduced operational disruptions and enhance the overall efficiency of power distribution assets, guaranteeing strategic financial planning.

Adherence to international standards such as IEC 62271, ANSI/IEEE C37, ISO 9001, CE, and UL embodies the cornerstone of quality and reliability in switchgear manufacturing. These standards guarantee that high voltage switchgear manufacturers and global switchgear suppliers deliver products that meet rigorous safety and performance criteria. Partnering with a certified manufacturer mitigates risks, assuring compliance and enhancing operational efficiency.

| Standard | Focus Area |

|---|---|

| IEC 62271 | High Voltage Switchgear |

| ANSI/IEEE C37 | Circuit Breakers |

| ISO 9001 | Quality Management Systems |

| UL | Safety Standards |

Certified manufacturers offer assurance of adherence to these benchmarks, which is essential for industries requiring uninterrupted power supply and safety. Global suppliers align their products with these standards to maintain competitive advantage and reassure clients of their commitment to excellence.

Selecting the right high voltage switchgear manufacturer requires meticulous evaluation of key factors, including the manufacturer's industry reputation, product quality, compliance with standards, and the breadth of customer support services.

A common pitfall in supplier selection is an overemphasis on cost at the expense of long-term reliability and operational efficiency, which can lead to increased maintenance costs and system failures.

To avoid these mistakes, decision-makers should prioritize a balanced assessment of total cost of ownership, technological innovation, and the manufacturer's commitment to quality and excellence.

When evaluating high voltage switchgear manufacturers, industry experience and reputation emerge as critical factors underpinning the selection process. Established high voltage switchgear manufacturers offer profound expertise, ensuring quality and reliability. Their longevity in the market signals successful navigation through industry challenges, enhancing their credibility.

An electrical switchgear factory known for its adherence to stringent standards and participation in industry associations bolsters trustworthiness. Moreover, the quality of products and technologies employed is paramount; advanced engineering and rigorous testing protocols guarantee operational safety and efficiency.

Customer support, including robust after-sales service, installation guidance, and efficient response times, is indispensable. Ultimately, balancing cost considerations with long-term value helps in making informed decisions, safeguarding investments against potential failures.

Though often overlooked, the process of selecting a high voltage switchgear manufacturer involves several important considerations that, if neglected, can lead to significant operational challenges.

A common mistake is undervaluing industry experience and reputation, which are essential for guaranteeing reliability and quality. Opting for the cheapest option without evaluating long-term value can result in higher costs due to frequent maintenance.

Ignoring the significance of smart switchgear technology may lead to inefficiencies and missed opportunities for enhanced system performance. Additionally, overlooking customer support capabilities can result in inadequate technical assistance when needed.

Extensive research into switchgear manufacturers USA, examining product certifications, and evaluating customer feedback are crucial steps. Prioritizing thorough after-sales service and advanced technology integration guarantees the best supplier selection.

In 2025, the high voltage switchgear market continues to be dominated by industry leaders such as ABB, Siemens, GE Vernova, Mitsubishi Electric, and Hitachi Energy, known for their innovative solutions and technological advancements.

These manufacturers prioritize reliability, safety, and efficiency in their product offerings, ensuring compliance with stringent industry standards. Their strategic investments in research and development, along with robust global distribution networks, position them at the forefront of addressing complex electrical infrastructure needs worldwide.

ABB, a prominent figure in the high voltage switchgear sector, consistently ranks among the top manufacturers worldwide due to its robust technological advancements and dedication to innovation.

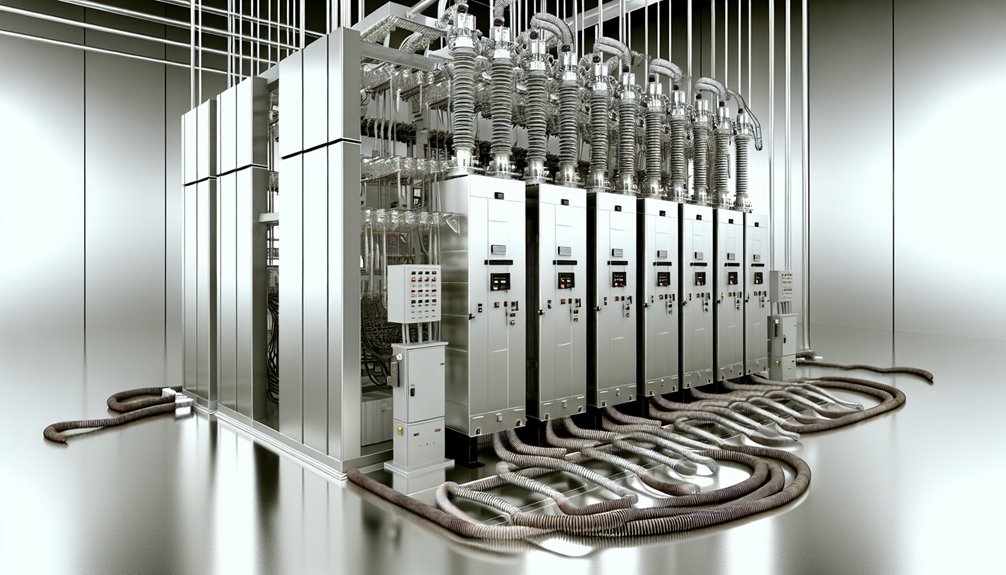

Known for its precision engineering, ABB offers a thorough range of gas insulated switchgear (GIS) and air insulated switchgear (AIS) solutions. These systems provide superior reliability and efficiency, meeting the rigorous demands of modern power systems.

ABB’s GIS technology is particularly valued for its compact design and reduced environmental impact, while AIS solutions excel in flexibility and cost-effectiveness.

Their advanced switchgear guarantees operational integrity and safety, backed by extensive testing and compliance with global standards.

ABB’s unwavering commitment to excellence empowers clients with control over their electrical infrastructures, guaranteeing long-term reliability and performance.

Siemens stands as a formidable entity in the high voltage switchgear industry, renowned for its cutting-edge technology and extensive solutions. Their portfolio encompasses a thorough range of products designed to enhance operational efficiency, safety, and reliability.

Siemens excels in delivering robust switchgear systems tailored to meet varying demands, ensuring compliance with stringent industry standards. Their innovative approach integrates digitalization and automation, providing clients with precise control over power distribution networks.

Siemens' dedication to research and development fosters advancements in smart grid solutions, bolstering energy management and sustainability efforts. Technical support and expert services further solidify their position as a leader, offering customized solutions that address specific needs while optimizing lifecycle costs.

Siemens remains a pivotal choice for discerning clients prioritizing control and performance.

GE Vernova, a leading entity in the high voltage switchgear sector by 2025, exemplifies cutting-edge engineering and design excellence. Their switchgear solutions are meticulously crafted, integrating advanced technologies to meet stringent industry standards.

GE Vernova's commitment to innovation is evidenced by their incorporation of digital interfaces and diagnostics, enhancing operational efficiency and reliability. Their focus on modular designs allows for scalability, catering to diverse power distribution requirements.

Rigorous testing protocols guarantee product durability and safety, aligning with regulatory compliance. GE Vernova's strategic investments in research and development reflect their dedication to addressing future energy challenges, positioning them as a pivotal player in sustainable energy solutions.

This dedication is mirrored in their thorough customer support, guaranteeing peak system performance and longevity.

Building upon the innovative strides seen in the high voltage switchgear sector, Mitsubishi Electric stands as a formidable contender among the top manufacturers by 2025. Their focus on integrating advanced technologies with precision engineering guarantees robust performance and reliability. Mitsubishi Electric's switchgear solutions are designed to meet stringent safety and efficiency standards, optimizing energy distribution and minimizing operational disruptions. Their commitment to sustainability is evidenced through the implementation of eco-friendly materials and practices.

| Feature | Description | Benefit |

|---|---|---|

| Advanced Technology | Precision engineering and smart monitoring systems | Enhanced reliability and real-time performance |

| Eco-friendly Materials | Sustainable manufacturing and SF₆-free insulation options | Reduced environmental impact and carbon footprint |

| Safety Standards | Compliance with IEC, ANSI/IEEE, and ISO certifications | Minimised operational risks and improved workplace safety |

Mitsubishi Electric continues to innovate, setting benchmarks in high voltage switchgear manufacturing with an analytical approach.

Hitachi Energy, a prominent player in the high voltage switchgear industry by 2025, exemplifies technological advancement and innovation in electrical systems.

It stands out by integrating cutting-edge technologies such as digitalization and smart grid solutions to enhance system efficiency and reliability.

With a commitment to sustainability, Hitachi Energy employs energy-efficient designs and materials, aligning with global environmental standards.

Their extensive portfolio includes gas-insulated switchgear (GIS) and air-insulated switchgear (AIS), catering to diverse industrial applications.

Emphasizing precision engineering, they guarantee robust performance and operational longevity.

Hitachi Energy's thorough technical support and maintenance services further optimize system uptime.

This strategic approach solidifies their reputation as a trusted provider of high-performance switchgear solutions, meeting the stringent demands of modern electrical infrastructures.

Toshiba, recognized as a top contender among high voltage switchgear manufacturers in 2025, exemplifies a commitment to technological prowess and innovation. Their advanced switchgear solutions integrate cutting-edge technology with robust engineering principles.

Toshiba's products are renowned for their reliability and efficiency, meeting stringent industry standards and certifications. Their extensive range includes GIS, AIS, and hybrid configurations, catering to diverse operational requirements.

Toshiba invests heavily in research and development, driving advancements in smart grid compatibility and energy management systems. This focus guarantees adaptability to evolving energy needs and regulatory landscapes.

Their thorough technical support and global service network further solidify Toshiba's standing, providing clients with reliable after-sales solutions, thereby reinforcing their position in the high voltage switchgear market.

Eaton, a prominent name in the high voltage switchgear domain, solidifies its position as a top manufacturer in 2025 through its commitment to innovation and engineering excellence.

The company's strategic focus on enhancing electrical system efficiency is evident in its advanced product offerings and technological advancements. Eaton's dedication to quality is reflected in its adherence to rigorous standards, ensuring reliability and safety for its clients.

Such factors position Eaton as a leader in the industry.

Building upon the innovation and engineering excellence exemplified by Eaton, CHUANLI emerges as a formidable contender within the sphere of high voltage switchgear manufacturers in 2025. Their commitment to precision engineering and superior technology positions them strategically within the industry. By leveraging robust research and development, CHUANLI innovates in the fields of automation and smart grid integration, enhancing operational efficiency and reliability.

| Feature | Description | Benefits |

|---|---|---|

| Automation | Advanced control and monitoring systems | Improved operational efficiency and reduced downtime |

| Smart Grid Integration | Seamless connectivity with digital power networks | Enhanced grid reliability and energy management |

| Precision Engineering | High-quality components and strict manufacturing standards | Increased product lifespan and performance stability |

| R&D Focus | Continuous innovation in design and materials | Access to cutting-edge technology and modern solutions |

| Global Reach | Extensive international distribution network | Broader market accessibility and faster project delivery |

Their global reach and strategic partnerships solidify CHUANLI's standing as a pivotal player in the high voltage switchgear sector.

CHINT Group, a prominent player in the high voltage switchgear industry, has established itself as a key manufacturer by leveraging advanced technology and a strong commitment to quality.

Their strategic focus on innovation and stringent quality control has led to robust product offerings. CHINT Group excels in three critical areas:

Their unwavering dedication to quality and innovation solidifies their position as a leader in the switchgear sector.

At Conya Electric, we are proud to be recognised among the top 10 high voltage switchgear manufacturers in 2025. Our ongoing commitment to innovation, precision, and quality drives everything we do. We focus on developing high-performance switchgear solutions that set new benchmarks for operational reliability, safety, and energy efficiency.

Every product we design and manufacture is engineered with meticulous attention to detail and fully compliant with the most stringent international standards. Serving clients across the globe, we ensure our solutions deliver both technical excellence and long-term dependability.

| Feature | Impact | Emotion Evoked |

|---|---|---|

| Innovation | Technological Advancement | Excitement |

| Reliability | Consistent Performance | Confidence |

| Compliance | Alignment with Global Standards | Trust |

| Global Reach | Support for Diverse Markets | Connection |

We believe in building more than just products — we build partnerships. Through our dedicated technical support, customisable engineering services, and value-driven approach, we continue to empower our partners to succeed in an evolving electrical landscape.

👉 Partner with Conya Electric today to explore tailored high-voltage switchgear solutions engineered for safety, reliability, and long-term performance.

Contact our technical team to discuss your next project or OEM collaboration.

The United States is home to some of the most prominent manufacturers in the switchgear industry, including North American Switchgear, Bay Power, Switchgear Power Systems (SPS), Volta, and Phoenix Electric Corp.

These companies contribute greatly to the sector with their extensive product portfolios, ranging from low to high voltage solutions, and maintain adherence to stringent industry standards.

Their strategic focus on innovation, quality assurance, and customer-centric services has solidified their status as leaders in the field, ensuring reliable electrical infrastructure across various applications.

Founded in 1980, North American Switchgear has established itself as a vital player in the U.S. switchgear market, specializing in both new and reconditioned electrical equipment.

The company offers an extensive inventory, particularly excelling in air circuit breakers and vintage equipment repair. Their commitment to quality is demonstrated through rigorous testing and compliance with industry standards, ensuring reliability and operational integrity.

Significant attributes include:

Through these strengths, North American Switchgear continues to serve a vital role in the electrical sector.

Following the notable impact of North American Switchgear in the market, Bay Power emerges as another significant player within the U.S. switchgear industry. Established in 1992, Bay Power focuses on providing a thorough array of electrical products, including switchgear and transformers.

Catering to varied requirements, they offer new, used, and obsolete parts, underscoring their adaptability in meeting diverse client needs. With over 30 years of industry experience, Bay Power emphasizes enhancing knowledge and expertise among manufacturers and distributors.

Their commitment to quality is evident through rigorous testing and adherence to industry standards. By maintaining a robust inventory, they guarantee prompt availability of components, facilitating efficient delivery and minimizing potential system downtime for their clients.

Switchgear Power Systems (SPS) stands as a prominent figure in the U.S. switchgear manufacturing landscape, renowned for its custom switchgear assemblies and innovative power control solutions. Their commitment to precision and high-quality standards is evident in every phase of production, from design to engineering.

SPS's strategic focus on competitive pricing complements their high-quality product offerings.

Key aspects of SPS's success include:

Through these efforts, SPS consistently delivers reliability and satisfaction to its clientele.

Volta stands out as a distinguished entity in the domain of switchgear manufacturing in the USA, distinguished by its century-long expertise in industrial power systems.

This company excels in producing custom switchgear assemblies and integrated power distribution systems, showcasing a profound understanding of complex industrial requirements.

Volta's dedication to project management and customer satisfaction is evident through its expanding customer base, attributable to effective problem-solving capabilities.

Their technical prowess is further supported by a robust quality assurance framework, ensuring compliance with stringent industry standards.

By offering thorough solutions tailored to specific applications, Volta meets and often exceeds client expectations, reinforcing its reputation as a leader in the field.

This commitment to excellence positions Volta as a preferred partner for demanding industrial projects.

As a family-owned enterprise with a rich history dating back to 1973, Phoenix Electric Corp. has carved a significant niche in the field of electrical contracting and switchgear manufacturing within the USA.

Their expertise extends over 50 years, focusing on delivering customized solutions tailored to complex electrical requirements. The corporation's commitment to precision and control is exemplified through several key attributes:

RESA Power stands as a pivotal entity within the landscape of leading switchgear manufacturers in the USA. The company specializes in providing high-quality power solutions, guaranteeing the reliability and safety of electrical infrastructures.

RESA Power's offerings encompass an extensive range of switchgear products, meticulously designed to meet stringent industry standards. Their expertise extends to custom-engineered solutions, catering to specific operational demands.

With a focus on precision and performance, RESA Power employs advanced technologies to enhance system efficiency and durability. Their commitment to rigorous testing protocols guarantees operational integrity, minimizing risks associated with electrical failures.

Through strategic partnerships and continuous innovation, RESA Power maintains a competitive edge, delivering solutions that align with evolving market requirements and regulatory compliance.

Prime Power distinguishes itself as a leading force among switchgear manufacturers in the USA, leveraging its robust technical expertise and industry experience to deliver superior electrical solutions.

Their commitment to quality and innovation is evident in their extensive product offerings, which are meticulously engineered to meet diverse customer requirements.

Such strategic advantages position Prime Power as a pivotal player in the high voltage switchgear market.

Southwest Electric Company, a venerable institution established in 1946, stands as a beacon of expertise in the switchgear manufacturing sector in the USA. The company delivers an extensive range of products including switchgear, transformers, and custom distribution transformers. Their focus extends to energy generation companies and diverse industrial markets.

Emphasizing compliance and safety, Southwest Electric offers advanced engineering, design, and preventive maintenance services. Their national field service guarantees peak operational integrity, aligning with industry standards and regulatory requirements.

The company’s commitment to rigorous testing and quality assurance, combined with its technical prowess, positions it as a pivotal player in securing electrical systems' reliability and efficiency. Southwest Electric's distinguished legacy underscores its pivotal role in the high voltage switchgear landscape.

In the high voltage switchgear industry, global OEMs are distinguished by their expansive reach and ability to offer standardized, high-volume production capabilities, while regional specialists excel in providing tailored solutions and localized support.

Choosing between a domestic and international supplier involves evaluating factors such as supply chain resilience, compliance with local regulations, and the ability to meet specific project requirements.

An analytical review of these elements will guide decision-makers in selecting the ideal partner for their operational needs.

While both global Original Equipment Manufacturers (OEMs) and regional integrators play critical roles in the switchgear industry, they differ markedly in scope, capability, and market focus.

Global OEMs possess extensive resources allowing for large-scale production and innovation, offering thorough product lines with advanced features. Their market reach extends internationally, supported by robust distribution networks and strategic alliances.

Conversely, regional integrators focus on localized needs, offering tailored solutions with in-depth knowledge of regional regulatory requirements and customer preferences. They excel in flexibility and responsiveness to market changes.

How does one decide between choosing a domestic supplier or an international one, particularly when weighing the merits of global leaders against regional specialists? The decision hinges on critical factors such as logistical efficiency, compliance with local regulations, and supply chain reliability.

Domestic suppliers offer advantages regarding reduced lead times and easier regulatory alignment, guaranteeing swift integration into existing systems. Conversely, international suppliers, often global leaders, provide access to advanced technologies and economies of scale. However, they may face challenges such as customs delays and increased complexity in communication.

An analytical approach requires evaluating the specific project demands, cost implications, and potential risks associated with each option. This guarantees a well-informed, strategic supplier selection that aligns with operational objectives.

The high voltage switchgear manufacturing sector is witnessing significant transformations driven by the shift towards SFfree and eco-friendly designs, responding to environmental regulations and sustainability goals.

Concurrently, there is a marked increase in the adoption of smart and digital switchgear systems, propelled by the demand for enhanced grid reliability and real-time data monitoring.

Additionally, the rise of renewable energy projects and grid modernization initiatives necessitates modular manufacturing approaches and compact substation designs, facilitating efficient space utilization and scalability.

As environmental concerns increasingly shape industry standards, high voltage switchgear manufacturers are pivoting towards SFfree and eco-friendly designs to address the global warming potential of traditional SFgas.

The change is driven by several key factors:

This shift reflects a broader commitment to sustainability in the high voltage switchgear sector.

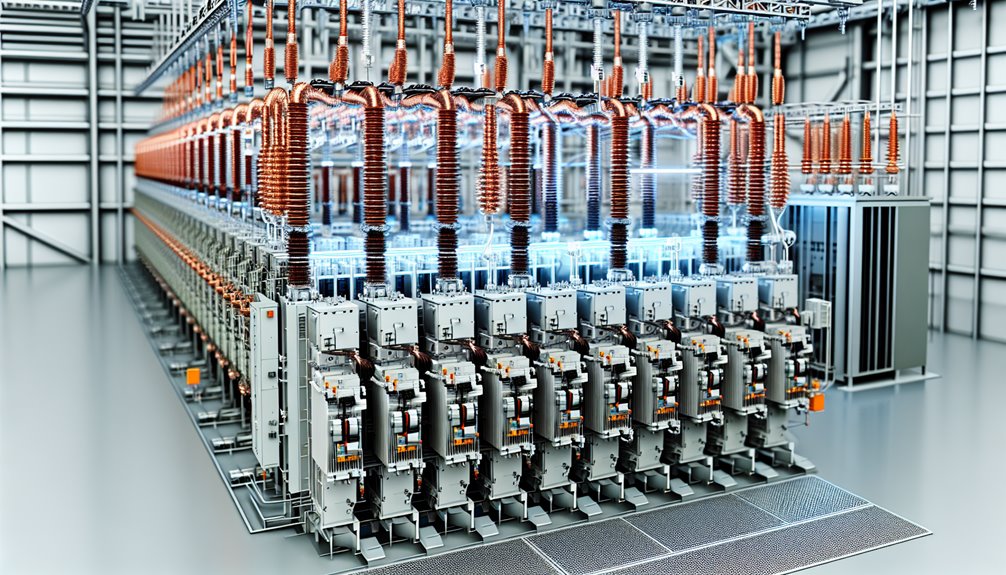

With the rapid advancement of technology, the high voltage switchgear sector is undergoing a significant transformation towards smart and digital systems. This shift is driven by the increased adoption of smart grids and digital substations, facilitating enhanced monitoring and control capabilities. The preference for gas-insulated switchgear (GIS) aligns with this trend, offering compactness and reliability. Regulatory pressures for SF6-free solutions further propel innovation in digital switchgear technologies.

| Trend | Impact | Example Technologies |

|---|---|---|

| Smart Grids | Improved efficiency, monitoring, and reliability across power networks | IoT-based control systems, AI-driven automation |

| Digital Substations | Enhanced real-time data analytics and remote diagnostics | Advanced sensors, digital relays, cloud platforms |

| SF₆-Free Solutions | Better environmental compliance and reduced greenhouse gas emissions | Eco-efficient switchgear using alternative gases |

| Gas-Insulated Switchgear (GIS) | Compact design for space-saving and high reliability | High-voltage GIS systems for urban substations |

| Regulatory Developments | Continuous innovation driven by evolving standards | New IEC/IEEE protocols and regional safety codes |

These developments reflect a strategic move toward future-ready electrical infrastructure.

Driven by the accelerating shift towards sustainable energy, the growth of renewable energy and grid modernization projects is considerably shaping the high voltage switchgear manufacturing industry. This evolution is underscored by several pivotal factors:

The high voltage switchgear manufacturing industry is undergoing a transformation with the advent of modular manufacturing and compact substation design. These innovations address the growing demand for efficient, scalable, and environmentally conscious solutions in power distribution. Modular systems facilitate rapid deployment and adaptability, essential for urban and industrial expansion. Compact substations, integrated with digital technologies, optimize space usage and enhance operational reliability.

| Feature | Benefit |

|---|---|

| Modular Manufacturing | Greater flexibility in design, installation, and system expansion |

| Compact Substation Design | Improved space utilisation and reduced overall project costs |

| Digital Integration | Enhanced system monitoring, predictive maintenance, and remote control capabilities |

Such advancements are particularly significant in regions experiencing rapid urbanization and industrial growth. They align with the regulatory push for sustainable energy solutions, providing a structured approach to modernizing infrastructure while minimizing environmental impact.

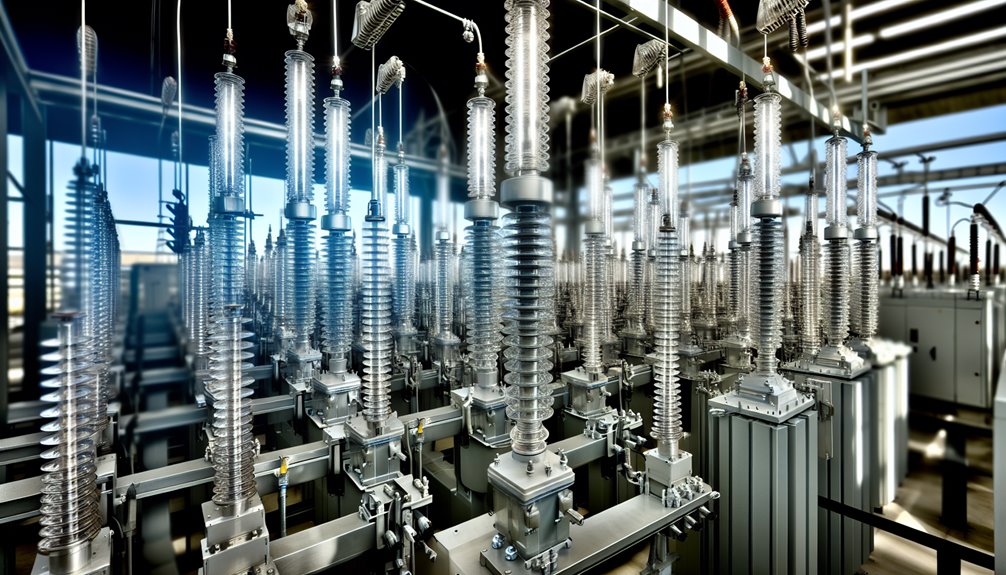

The implementation of type-testing and routine testing standards is critical in ensuring the safety and reliability of high voltage switchgear systems.

Predictive maintenance and condition monitoring techniques are increasingly being adopted to preemptively address potential failures, thereby enhancing system uptime and operational efficiency.

Additionally, retrofitting and lifecycle extension solutions offer cost-effective strategies to upgrade existing switchgear infrastructure, extending their usable life and improving performance metrics.

When confirming the reliability and safety of switchgear systems, understanding the significance of type-testing and routine testing standards becomes essential.

These standards delineate the procedures and criteria to verify the performance, durability, and safety of switchgear equipment under various conditions.

This structured approach enables manufacturers to deliver switchgear solutions that meet stringent quality and safety benchmarks.

As industries increasingly prioritize operational efficiency, predictive maintenance and condition monitoring emerge as critical components in maintaining switchgear systems. These practices enable the anticipation of equipment failures and the optimization of maintenance schedules, thereby minimizing unplanned downtime.

Predictive maintenance utilizes advanced technologies such as thermal imaging, vibration analysis, and real-time data acquisition to assess the health of switchgear components. Condition monitoring further enhances this by providing continuous oversight of system performance and identifying anomalies that may indicate impending faults.

Implementing these strategies allows operators to make informed decisions, ensuring the longevity and reliability of switchgear assets. Consequently, these methodologies contribute considerably to operational reliability and cost efficiency, aligning with industry demands for proactive and data-driven maintenance solutions.

Predictive maintenance and condition monitoring set the stage for exploring retrofitting and lifecycle extension solutions, which encompass maintenance, testing, and quality assurance strategies. These solutions are pivotal for extending the operational lifespan of switchgear systems while ensuring ideal performance and reliability.

A detailed analytical approach to these strategies involves:

Such strategies provide control over system longevity and operational efficiency.

To effectively request a quotation or establish an OEM partnership with high voltage switchgear manufacturers, it is vital to prepare thorough technical data, including specifications and performance requirements.

Typical lead times and delivery considerations should be analyzed to guarantee alignment with project timelines and logistical constraints.

Additionally, maintaining a detailed documentation and certification checklist is essential for verifying compliance with industry standards and facilitating a seamless procurement process.

When preparing to request a quotation or an OEM partnership for switchgear manufacturing, it is crucial to compile thorough technical data to guarantee clarity in communication and accuracy in the proposals received. This data serves as the foundation for understanding specific needs and expectations.

Essential components include:

Each element contributes to a well-defined request, aiding manufacturers in crafting informed, precise responses tailored to unique operational demands.

Understanding lead times and delivery considerations is critical when requesting a quotation or seeking an OEM partnership for switchgear manufacturing.

Manufacturers often provide lead times based on production schedules, current demand, and component availability. Potential partners should account for these factors to align expectations and project timelines accurately.

Analyzing historical lead time data can offer insights into a manufacturer's reliability and responsiveness.

Delivery considerations include shipping logistics, customs clearance for international orders, and potential delays due to unforeseen circumstances. Prospective clients must inquire about expedited options and the manufacturer's flexibility in accommodating urgent requests.

Precise communication regarding delivery terms and conditions is essential to avoid misalignment. Consequently, engaging with manufacturers who demonstrate transparency and adaptability in lead times fosters a productive partnership.

Precision is paramount when requesting a quotation or seeking an OEM partnership with switchgear manufacturers. A meticulous approach guarantees clear communication and facilitates a seamless process.

The documentation and certification checklist should encompass detailed specifications and compliance with industry standards. To streamline the process, consider the following essential steps:

High voltage switchgear manufacturing impacts the environment through resource extraction, energy consumption, and emissions. It necessitates mining for materials, consumes considerable energy during production, and generates waste, prompting the need for sustainable practices and pollution control measures.

Manufacturers implement advanced encryption, robust access controls, and continuous monitoring systems. They conduct regular cybersecurity audits, integrate secure communication protocols, and collaborate with cybersecurity experts to protect against threats, ensuring system integrity and unauthorized access prevention.

In the domain of high voltage switchgear production, sustainability is the linchpin driving innovation. Manufacturers employ eco-friendly materials, optimize energy usage during manufacturing processes, and implement recycling protocols, ensuring a reduced environmental footprint without sacrificing operational integrity.

Emerging innovations in high voltage switchgear technology include integration of digital monitoring systems, advancements in insulation materials for enhanced durability, incorporation of eco-friendly gases like fluoronitrile, and development of compact designs that facilitate space-efficient installations while maintaining operational reliability.

Manufacturers address supply chain disruptions by diversifying supplier networks, employing advanced inventory management systems, and adopting flexible production techniques. They implement strategic risk assessments and collaborate with logistics partners to guarantee resilience and maintain continuity of operations despite challenges.

In the domain of high voltage switchgear manufacturing, envision a complex tapestry of intricate circuits and robust enclosures, where precision engineering meets cutting-edge innovation. As manufacturers forge pathways through this electrified landscape, the confluence of quality, compliance, and sustainability forms a triad of excellence. These companies, akin to steadfast sentinels, guarantee the seamless flow of electricity, safeguarding industries against disruptions and fortifying the global pursuit of a sustainable energy future, one meticulously crafted component at a time.