In today’s industrial and commercial environments, electrical reliability is non-negotiable. At the heart of every safe and efficient power distribution system lies low voltage switchgear—the equipment responsible for controlling, protecting, and isolating electrical circuits. But even the most advanced switchgear cannot deliver long-term performance without regular, standards-based testing.

Following a structured low voltage switchgear testing procedure is essential to ensure equipment functions as intended, complies with international standards, and safeguards both people and assets. Without proper testing, organizations risk costly downtime, electrical failures, or even catastrophic safety incidents.

This guide provides a step-by-step breakdown of the most critical LV switchgear testing methods—ranging from insulation resistance checks to functional circuit breaker tests. Whether you’re commissioning new equipment or maintaining existing systems, these procedures will help you achieve greater reliability, compliance, and return on investment.

Low voltage switchgear is a coordinated assembly of devices designed to control, protect, and isolate electrical equipment operating at voltages up to 1,000 volts AC (or 1,500 volts DC). It is a core part of power distribution systems, ensuring safe operation, reliable performance, and protection against electrical faults.

A typical LV switchgear assembly includes several essential devices:

These components are housed in a metal-enclosed structure that prioritizes safety while allowing accessibility for inspection and maintenance.

Low voltage switchgear is widely used wherever safe and efficient power distribution is required:

To guarantee performance and safety, low voltage switchgear testing and operation must comply with international standards, including:

Meeting these standards ensures reliability, reduces operational risks, and provides assurance that the switchgear will perform under demanding conditions.

Built to IEC 61439 performance criteria, an LV switchgear assembly only achieves its intended safety and reliability when routine verification confirms that as-installed conditions match the verified design.

Testing validates conformity to testing standards, evidencing electrical safety and functional integrity under defined performance metrics. It establishes a traceable reliability assessment, closing gaps introduced by installation variances, environmental factors, or component substitutions.

Routine tests also underpin risk management by identifying degradation, misconnections, and protection coordination defects before energization and during lifecycle maintenance.

Measured outcomes—insulation resistance, dielectric withstand margins, protective circuit continuity, and mechanical actuation consistency—provide objective data for acceptance and ongoing condition monitoring.

Documented results create accountability, support regulatory compliance, and enable controlled change.

Without disciplined testing, residual hazards and latent failure modes remain unmanaged.

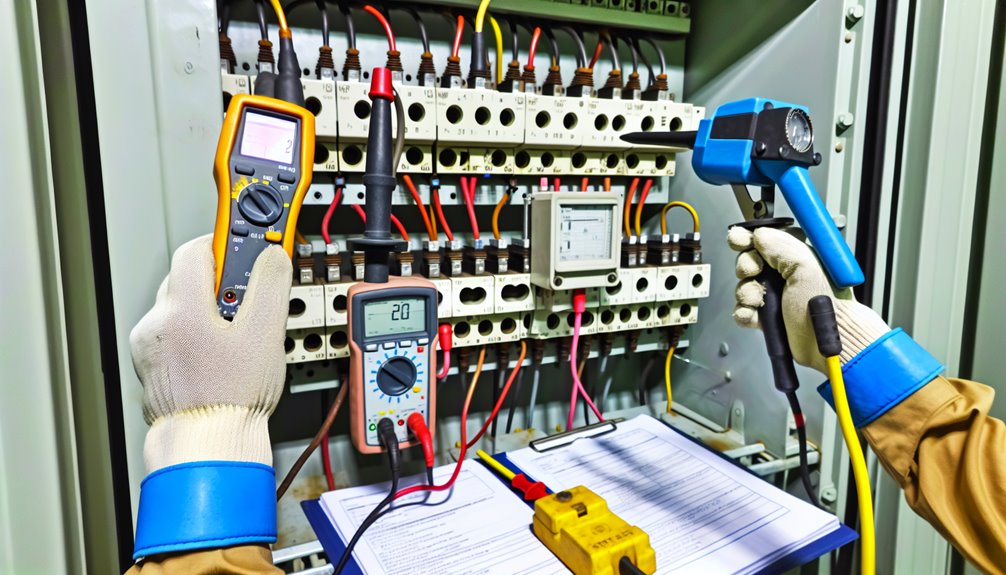

The step-by-step procedure begins with visual and mechanical inspection to verify IP rating, labeling, clearances, torque, and wiring integrity against IEC 61439 requirements.

It proceeds to insulation resistance testing and dielectric withstand (HiPot) with appropriate isolation of sensitive devices, followed by contact resistance measurements to confirm low-impedance main paths.

Finally, functional testing validates circuit breaker operations and protective relay settings, sequencing, and interlocks under controlled conditions.

Before any electrical testing, a systematic visual and mechanical inspection verifies that the LV switchgear assembly is safe, compliant, and ready for energization.

The inspector executes visual inspections against drawings and IEC 61439, confirming mechanical integrity, adherence to safety protocols, clear equipment labeling, and decisive operational checks.

Focus remains on enclosure condition, mounting clearances, IP compliance, interlocks, door operation, torque settings, conductor routing, and identification.

Although visual and mechanical checks precede it, insulation resistance testing establishes the baseline dielectric condition of low voltage switchgear prior to energization. The procedure aligns with testing standards such as IEC 61439-1.

All connected devices are isolated; the assembly is de-energized and discharged. Megohmmeter usage applies a minimum 500 VDC to measure between phases, phase-to-neutral, and phase-to-exposed conductive parts. Target values include .5 MΩ for 230/400 V assemblies and MΩ for higher classes.

Ambient temperature and humidity are recorded for voltage correction and temperature normalization. Readings at 30 s and 1 min are captured; optional PI and DAR support diagnostics of insulation materials.

Safety precautions include verified lockout-tagout, barriers, test leads rated for the applied voltage, and controlled ramp-up/down to prevent transients.

Following insulation resistance verification, dielectric withstand testing applies a specified AC or DC test voltage between each live pole and exposed conductive parts, and between segregated circuits, to confirm clearances per IEC 61439-1 without stressing intrinsic insulation properties.

The objective is to prove the assembly’s immunity to Dielectric breakdown for at least 1 second with no flashover. Testing equipment shall ramp from 0 V, stabilize at the prescribed test voltage, then return to 0 V, observing strict Safety precautions and lockout.

Even after dielectric verification, contact resistance testing quantifies the ohmic integrity of main current paths—busbar joints, disconnects, and breaker main contacts—to confirm low-loss performance and compliance with IEC 61439-1 routine verification.

Testing methods employ a four-wire Kelvin micro-ohmmeter with stabilized DC current, ensuring measurement accuracy by eliminating lead and junction effects.

Preparations include de-energization, isolation of sensitive electronics, clean and tightened terminals, and equipment calibration traceable to ISO/IEC 17025.

Inject current per manufacturer or standard guidance, record stabilized micro-ohm values, and compare against acceptance criteria and type-test benchmarks. Document temperature and correct readings where required.

Define testing frequency within the maintenance strategy, increasing cadence for high-load or high-cycle assets. Investigate elevated values for contamination, looseness, or damaged joints; rectify and re-test.

Functional testing of circuit breakers and protective relays validates correct operation of protection, control, and signaling functions under defined conditions before energization. The process confirms circuit breaker operation and protective relay functionality using defined testing methodologies aligned to electrical safety protocols and compliance standards (IEC 61439, IEC/IEEE 60255, NFPA 70E). Results are recorded, with pass/fail criteria traceable to settings sheets and manufacturer data.

All tests proceed under lockout-tagout, barriers in place, and documented risk controls.

Although routine verification guarantees baseline compliance, optional and advanced tests provide deeper assurance of insulation health, interlocking integrity, and system resilience under abnormal conditions.

Advanced testing methods include polarization index trending, partial discharge screening on busbars and cables, and thermographic surveys under load to expose latent defects.

Optional performance assessments cover arc-flash mitigation scheme validation, breaker contact resistance trending, and door-coupled interlock stress cycles beyond type-test minima.

Innovative testing technologies such as wireless temperature sensors, online power quality analyzers, and digital torque verification improve repeatability and traceability.

Safety protocol enhancements mandate energized work risk assessments, remote racking where applicable, and lockout-tagout verification before elevated-stress trials.

Thorough testing strategies should be aligned with IEC 61439, manufacturer limits, and documented acceptance criteria, including environmental conditions and measurement uncertainty.

A structured checklist helps ensure that no step in the low-voltage switchgear testing procedure is overlooked. The following list can serve as a quick reference for engineers and maintenance teams during inspections and testing.

| Test / Inspection | Purpose | Standard Reference | Pass/Fail | Notes |

|---|---|---|---|---|

| Visual & Mechanical Check | Detect damage, misalignment, loose parts | IEC 61439, IEC 60204 | ☐ / ☐ | |

| Insulation Resistance Test | Verify insulation quality & detect leakage | IEC 60204, Manufacturer spec | ☐ / ☐ | |

| Dielectric Withstand (HiPot) Test | Confirm insulation can withstand overvoltage | IEC 61439 | ☐ / ☐ | |

| Contact Resistance Test | Ensure low-resistance connections for efficiency | IEEE Std 81 | ☐ / ☐ | |

| Circuit Breaker Functional Test | Verify trip settings, timing & protection | Manufacturer test sheets | ☐ / ☐ | |

| Relay Calibration | Confirm correct settings & fault coordination | IEC/IEEE standards | ☐ / ☐ | |

| Earth Continuity Test | Ensure grounding integrity & safety | IEC 60204 | ☐ / ☐ | |

| Temperature Rise Check | Prevent overheating under load | IEC 61439 Type Testing | ☐ / ☐ |

Conya recommends creating a standardized, documented checklist for every round of LV switchgear testing. This not only ensures compliance with IEC and IEEE standards but also creates a reliable maintenance history for audits and inspections.

Even when testing procedures are well-documented, errors can occur during the execution phase. These mistakes can reduce the reliability of results, compromise safety, and even damage critical equipment. Recognizing and avoiding these pitfalls is just as important as performing the tests themselves.

Some teams go straight to electrical testing without confirming the physical condition of the switchgear. Cracks, corrosion, loose connections, or incorrect labeling can all lead to inaccurate results or hidden hazards.

Best Practice: Always start with a thorough visual and mechanical inspection before electrical measurements.

Accurate readings depend on properly calibrated testing equipment. Outdated megger testers, micro-ohm meters, or relay test sets can produce misleading results.

Best Practice: Maintain a schedule for calibration and verification of all testing instruments, aligned with ISO/IEC 17025 guidelines where applicable.

Relying only on general testing values can lead to misjudgments, as acceptable ranges often differ by switchgear type and design.

Best Practice: Cross-check results with manufacturer datasheets and international standards such as IEC 61439 or IEC 60204.

Without detailed records, it becomes difficult to track trends in equipment condition or demonstrate compliance during audits.

Best Practice: Use standardized forms or digital logs to record every measurement, test date, and inspector signature.

Insulation and resistance tests alone do not confirm the protective functions of LV switchgear. Failing to simulate fault conditions leaves systems vulnerable.

Best Practice: Always include breaker trip tests and relay verification as part of the routine testing sequence.

Applying high voltage without proper isolation or PPE (personal protective equipment) exposes technicians to serious risks.

Best Practice: Follow lockout/tagout (LOTO) procedures, wear arc-rated PPE, and ensure all safety barriers are in place before applying test voltages.

Avoiding these pitfalls ensures that low voltage switchgear testing procedures deliver accurate, reliable, and safe results. A disciplined approach—combining proper preparation, calibrated tools, adherence to standards, and complete documentation—helps extend equipment life while reducing operational risks.

Why prioritize maintenance within the LV switchgear lifecycle? A disciplined lifecycle management plan, aligned with IEC 61439 and OEM guidance, delivers measurable reliability enhancement, operational efficiency, and cost reduction.

Maintenance strategies integrate condition-based inspections, calibrated testing, and documented interventions to control risk and sustain performance.

Planned outages, spares provisioning, and clear escalation paths guarantee safe work execution.

Evidence-based decisions extend service life and preserve arc-flash boundaries.

Annual testing suits offices; semiannual for hospitals and data centers; quarterly for heavy industry. Test frequency guidelines reflect facility type considerations, routine maintenance importance, regulatory compliance standards, and risk assessment strategies, adjusting intervals for load criticality, environmental stress, and fault history.

Certification requirements include IEC/ISO familiarity, electrical qualification, and documented safety training. Technical expertise with test instruments and standards is mandatory. Continuing education sustains competence. Objection—“experience suffices”—is rejected; industry standards demand certified, periodically revalidated personnel for controlled, auditable testing accountability.

Insulation testers, dielectric testers, micro-ohmmeters, RCD testers, clamp meters, torque tools, and multimeters require calibration. Calibration frequency: 62 months, per Accuracy standards and Compliance requirements, adjusted for Environmental factors, utilization, drift history, and manufacturer guidance, with traceable certificates.

They archive test data in secure electronic records with controlled access, standardized metadata, and versioning. Data storage aligns with audit requirements, compliance standards, and data retention policies, ensuring traceability, integrity, and tamper-evidence, with backups, time-stamps, calibration links, and change logs.

Adaptations include environmental sealing to IP/Type standards, corrosion resistant materials, protective coatings, humidity control, and derating for temperature extremes. They specify stainless hardware, sealed glands, anti-condensation heaters, filtered ventilation, sacrificial protection, and periodic inspections per IEC/UL, ensuring safety margins and controlled reliability.

Reliable low voltage switchgear testing procedures are essential for safe, efficient, and long-lasting electrical systems. From visual inspections to advanced relay coordination, every test plays a role in preventing failures, reducing downtime, and ensuring compliance with international standards.

When executed systematically—with the right tools, documentation, and expertise—testing becomes a strategic investment in operational continuity and safety.

At Conya, we support organizations across industrial, commercial, and renewable energy sectors with advanced switchgear solutions and testing guidance. Our approach combines technical precision with practical application, ensuring that every system we deliver meets the highest standards of reliability.

Whether you need expert advice, tailored solutions, or guidance on LV switchgear testing best practices, Conya is here to help.

Contact our team today to learn how our switchgear solutions and technical expertise can safeguard your operations and prepare your infrastructure for the future.