Custom electrical switchgear represents a critical innovation in power distribution systems, tailored to specific project needs across various sectors. It combines advanced design elements with precise component selection, enhancing safety and performance. With features such as arc-flash mitigation and modular construction, it offers scalability and integration capabilities. These attributes make it a versatile solution, aligning with evolving operational demands and industry standards. Understanding its intricacies provides valuable insights into optimizing electrical infrastructure.

Custom electrical switchgear represents a specialized category of power distribution equipment meticulously engineered to satisfy distinct project specifications.

It is designed to address specific operational, safety, and environmental requirements that standard switchgear cannot accommodate. Custom switchgear provides tailored configurations, allowing for unique layouts and enclosure designs that can handle non-standard voltages, currents, and fault ratings.

This custom approach enables seamless integration with automation systems, SCADA, UPS, and generators, ensuring ideal performance in industrial, commercial, and mission-critical environments.

Additionally, custom electrical switchgear is versatile, supporting low, medium, and high voltage applications while adhering to stringent industry standards.

In the domain of custom switchgear, key design elements encompass precise component selection, including breakers, relays, and transformers, which are essential for achieving tailored performance.

The flexibility in layout and configuration allows for bespoke solutions, accommodating various operational environments and safety requirements.

Additionally, the ability to integrate with systems such as UPS, SCADA, and advanced protection systems across LV, MV, and HV voltage classes guarantees seamless and efficient power management tailored to specific project demands.

A pivotal aspect of designing custom switchgear is the meticulous selection of components, including breakers, relays, and transformers.

In custom LV switchgear, component selection is driven by the specific electrical and operational requirements of the application. Breakers must provide precise protection and fault interruption capabilities tailored to the system's voltage and current ratings.

Relays are chosen to guarantee accurate fault detection and coordination, enhancing system reliability. Transformers are selected based on their ability to efficiently handle load demands while maintaining voltage regulation.

Each component is evaluated for compatibility, performance, and integration within the custom switchgear system. This analytical approach guarantees that the switchgear operates effectively, maintaining control over power distribution, safety, and efficiency in diverse environments.

How does one achieve ideal performance and adaptability in power distribution systems? The answer lies in the layout and configuration flexibility of custom mv switchgear.

Through meticulous switchgear customization, projects can accommodate unique spatial constraints and operational requirements. This flexibility guarantees that the electrical setup aligns precisely with the architectural and performance demands of the installation site.

Custom mv switchgear allows for front or rear access, specialized compartmentalization, and arc-resistant designs, enhancing both safety and operational efficiency.

Voltage classification is a critical aspect of custom switchgear design, providing tailored solutions across low voltage (LV), medium voltage (MV), and high voltage (HV) applications. Each category addresses specific operational demands, guaranteeing ideal performance and safety. Custom electrical switchgear design accommodates various voltage levels, which are essential for diverse industrial and commercial needs. The precision in designing custom HV switchgear guarantees robust handling of high-energy loads, while LV and MV systems offer flexibility and safety for lower-energy applications.

| Voltage Class | Range | Application Example |

|---|---|---|

| LV | Up to 1kV | Commercial Buildings |

| MV | 1kV-38kV | Industrial Facilities |

| HV | Above 38kV | Substations |

This stratification guarantees custom switchgear meets the exacting requirements of different electrical environments.

Custom electrical switchgear is engineered to handle varying voltage classes, ensuring each system meets the specific demands of its operational environment.

Integration with UPS, SCADA, and protection systems is a critical aspect. Switchgear engineering services specialize in designing custom power distribution equipment that seamlessly incorporates these technologies, ensuring robust power management and enhanced control.

UPS integration guarantees an uninterrupted power supply, essential for mission-critical operations. SCADA systems provide real-time monitoring and automation capabilities, optimizing performance and response times.

Protection systems are meticulously configured to detect and isolate faults, safeguarding equipment and personnel. By tailoring each component to the specific application, custom switchgear facilitates superior reliability, safety, and efficiency, meeting the precise needs of complex electrical infrastructures.

In the domain of power distribution, custom switchgear plays a critical role by providing specialized solutions that enhance system reliability and safety. Utilizing UL 891 switchgear standards, these systems are meticulously designed and built to guarantee precise power management tailored to specific project needs.

Essential functions include protection, control, and isolation, safeguarding equipment and personnel from electrical faults. Custom switchgear facilitates seamless coordination among components, maintaining continuity for critical loads even in complex environments.

Custom electrical switchgear provides significant advantages regarding enhanced safety, optimized performance, and operational reliability.

By incorporating features such as arc-flash mitigation and interlocks, it guarantees superior protection for personnel and equipment.

Additionally, its capacity to be tailored for specific loads and to provide long-term flexibility supports uninterrupted power supply for mission-critical operations, while allowing for future upgrades and adaptability.

Although standard switchgear provides basic safety features, the enhanced safety of custom electrical switchgear is achieved through advanced arc-flash mitigation techniques and interlock systems.

Arc-flash mitigation is critical in reducing the risk of dangerous electrical arcs, which can lead to severe injuries and equipment damage. This is accomplished by incorporating arc-resistant designs and fast-acting protective devices that limit arc duration and energy.

Additionally, interlock systems guarantee that operations are performed in a safe sequence, preventing inadvertent access to live components and consequently minimizing human error. These systems are strategically integrated into the switchgear, providing an additional layer of protection.

As a result, custom switchgear not only meets but surpasses industry standards, offering superior safety and control in high-risk environments.

By tailoring electrical switchgear to the specific demands of a project, optimized performance for unique loads can be achieved. Custom switchgear allows precise adaptation to operational requirements, guaranteeing efficiency and reliability.

The following elements contribute to this optimization:

These features collectively guarantee that the switchgear meets precise load requirements efficiently.

Optimized performance for specific loads establishes a strong foundation for maximizing uptime in mission-critical operations.

Custom electrical switchgear is designed to maintain continuous operations by integrating uninterruptible power supplies (UPS) and redundancy. This guarantees critical systems remain operational even during power anomalies.

Precision-engineered configurations allow for seamless shifts between power sources, minimizing the risk of outages. Protective components such as circuit breakers and relays are selected to align with the exact specifications of the system, reducing fault occurrences.

Additionally, advanced monitoring and control systems enable real-time analysis and quick response to potential issues, enhancing reliability.

Custom electrical switchgear offers long-term flexibility and upgrade pathways by accommodating evolving power distribution needs. This adaptability guarantees that facilities can incorporate technological advancements without significant overhauls.

Key advantages include:

These features provide operators with control over their power distribution strategies, enhancing operational longevity.

A multitude of industries leverage custom switchgear for tailored power management solutions that address their specific operational challenges.

Data centers employ compact, high-uptime systems with advanced redundancy to support critical IT infrastructure.

Utilities and municipalities require robust systems for hospitals and universities, guaranteeing high reliability and complex source transfers.

In industrial and manufacturing sectors, custom switchgear manages heavy machinery, incorporating arc-resistant and explosion-proof designs for safety in hazardous conditions.

Renewable energy applications integrate custom switchgear for grid synchronization and control in solar and wind farms, often utilizing SCADA systems.

Commercial buildings optimize space with metal-enclosed designs for elevators and HVAC systems.

Additionally, microgrids benefit from custom solutions that manage multiple energy sources and guarantee seamless local grid operation.

The design and construction of custom electrical switchgear begin with a thorough evaluation of site conditions and load requirements, ensuring that all specifications are met.

Engineering teams utilize standards such as UL 891 and IEC 61439 to create precise layout designs, which are followed by meticulous component integration and fabrication processes.

Each unit undergoes rigorous Factory Acceptance Testing (FAT) to verify functionality and safety before commissioning, ensuring reliable operation tailored to specific applications.

Before starting on the design and construction of custom electrical switchgear, it is critical to conduct a thorough site and load evaluation. This assessment guarantees the switchgear will meet all operational and environmental demands.

The evaluation process involves several critical steps:

This meticulous evaluation provides the foundation for engineering a switchgear solution that is both efficient and reliable.

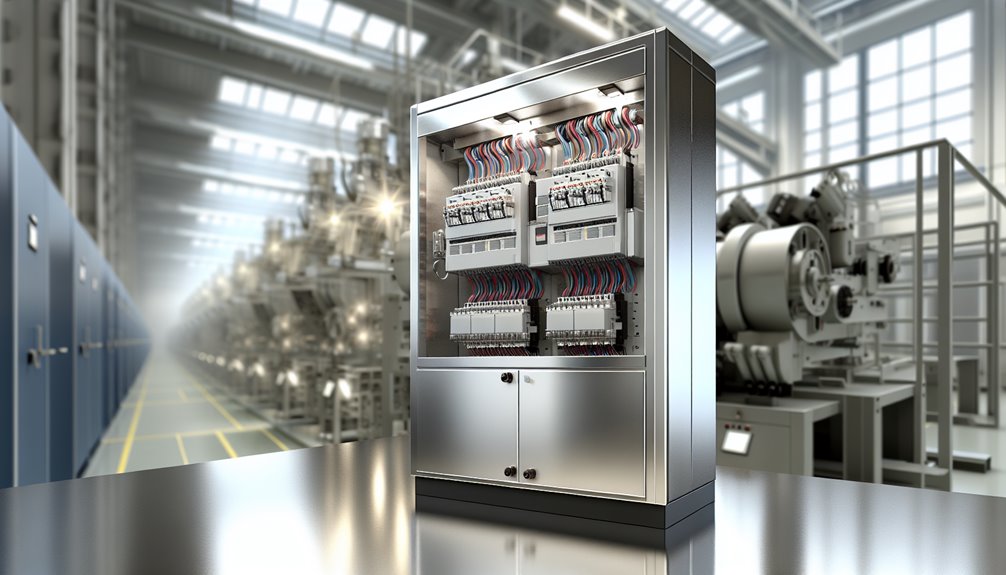

When starting on the engineering and layout design of custom electrical switchgear, understanding the unique operational and environmental demands is essential. This process begins with a thorough requirement analysis, focusing on voltage, current ratings, and site specifics.

Engineers employ CAD/CAE software to draft precise schematics, detailing busbar configurations and component placements within custom enclosures. Component selection is critical, utilizing high-quality breakers and relays from reputable manufacturers like ABB or Siemens to align with technical specifications and budget constraints.

The design adheres to standards such as UL 891 and IEC 61439, ensuring compliance and safety. Iterative feedback loops with stakeholders refine the design, optimizing it for seamless integration into its intended application, whether in data centers, hospitals, or industrial facilities.

Every custom electrical switchgear design begins with an in-depth requirement analysis, pinpointing exact voltage, current ratings, and site-specific needs. The process involves a meticulous engineering phase followed by precise fabrication.

Engineers employ CAD software to draft schematics, guaranteeing ideal component placement and enclosure dimensions.

Component integration encompasses the careful selection of high-quality parts. This involves:

The result is a bespoke solution tailored for environments such as data centers and industrial plants.

A critical phase in the development of custom electrical switchgear is the Factory Acceptance Testing (FAT), which serves as a thorough validation of the design and build process. This stage guarantees that each unit meets stringent functional, electrical, and safety standards before being dispatched.

FAT involves extensive testing, where components such as breakers, busbars, and internal wiring are scrutinized for performance and reliability. The testing phase verifies that the system operates as intended under various conditions, confirming adherence to specified technical requirements.

After successful testing, the commissioning phase follows, integrating the switchgear into the intended site layout. This guarantees seamless functionality, optimizing maintenance access and operational efficiency.

Such rigorous processes ensure a tailored, reliable power distribution solution.

Compliance with industry standards is essential for guaranteeing the reliability and safety of custom electrical switchgear. Adhering to recognized standards such as UL 891 for low voltage systems and UL 1558 for medium voltage systems guarantees that equipment meets rigorous safety and performance criteria.

Ensuring compliance with industry standards is key to the reliability and safety of electrical switchgear.

Standards like IEC 61439 and IEEE/ANSI provide guidelines for the construction, testing, and operation of switchgear, offering a benchmark for quality and safety.

Choosing certified systems reduces risk and enhances operational confidence.

How does one determine the best fit between custom and standard switchgear cabinets for a particular project? The decision hinges on several critical factors.

Standard switchgear cabinets offer pre-engineered solutions that are cost-effective and guarantee faster delivery times, making them ideal for simpler applications with universal components.

However, custom switchgear cabinets are essential when dealing with complex systems requiring tailored dimensions and integration with smart systems, guaranteeing optimized performance and compliance with specific regulations.

Project complexity, budget constraints, space availability, lead time, and compliance requirements are key considerations.

For example, a standard cabinet suits a small warehouse, while a custom cabinet is necessary for intricate environments like offshore oil platforms.

Consulting with reputable suppliers guarantees informed decision-making and project success.

When selecting a custom switchgear manufacturer, what essential criteria should be prioritized to guarantee suitable project outcomes? A discerning approach guarantees peak performance, safety, and reliability.

Key factors include:

These criteria collectively guarantee a strategic and informed selection process.

At Conya Electric, we specialise in custom-engineered switchgear solutions designed to meet real-world operational and compliance requirements. Founded in 1988, we bring decades of experience in electrical system engineering, supported by ISO-certified manufacturing processes and a mature quality management framework.

We design and manufacture low-, medium-, and high-voltage custom switchgear, tailoring layouts, protection schemes, and component selection to suit specific project conditions. Our systems are engineered to integrate seamlessly with globally recognised components from partners such as ABB, GE, and Eaton, ensuring technical compatibility, long-term availability, and proven performance.

Across power generation, industrial facilities, infrastructure, and new energy applications, our focus remains consistent: system safety, operational reliability, and lifecycle efficiency. Every custom switchgear assembly undergoes strict quality control and testing in accordance with ISO 9001 and China Compulsory Certification (3C) requirements.

By combining engineering depth, controlled manufacturing, and responsible energy practices, we support clients seeking reliable, application-specific switchgear solutions rather than off-the-shelf compromises.

Factors affecting the cost include design complexity, component quality, customization level, required certifications, installation environment, and integration needs. Each element demands precise engineering, impacting material choice, manufacturing processes, testing rigor, and final system performance, dictating overall expenses.

Manufacturing custom switchgear typically spans 12 to 24 weeks, contingent on design complexity, component availability, and project specifications. Detailed planning, precise engineering, rigorous testing, and quality assurance are essential to guarantee timely completion and peak performance.

Yes, custom switchgear can be upgraded or expanded post-installation. This involves evaluating existing configurations, designing adaptations for added components, and ensuring integration with current systems, ultimately enhancing functionality and accommodating increased power demands effectively.

Custom switchgear maintenance is akin to tuning a high-performance engine; regular inspections, cleaning, and testing are critical. Components like protective relays and circuit breakers require periodic calibration to guarantee peak functionality and prevent unexpected power disruptions.

Custom switchgear withstands extreme environmental conditions through robust enclosure designs, sealing against moisture and dust, employing corrosion-resistant materials, integrating climate control systems, and incorporating advanced thermal management to guarantee peak performance and reliability in harsh settings.

Custom electrical switchgear is not just a design preference—it is a strategic investment in safety, reliability, and long-term system performance. When power requirements, space constraints, environmental conditions, or operational continuity demand more than standard solutions, a purpose-built switchgear system delivers measurable advantages across the project lifecycle.

At Conya Electric, we work closely with engineers, contractors, and project owners to design and manufacture custom switchgear solutions that align precisely with technical specifications, compliance requirements, and operational goals. From low-voltage to high-voltage applications, our team supports projects with certified manufacturing, rigorous testing, and practical engineering insight.

If you are planning a new installation, system upgrade, or retrofit—and need a switchgear solution that fits your project, not the other way around—contact Conya Electric to discuss your requirements. Our specialists are ready to support your project from concept to commissioning.erm value.