Commercial electrical distribution refers to the structured system that safely delivers electrical power from utility sources to end-use circuits within commercial buildings. Unlike residential systems, commercial distribution must support higher loads, three-phase power, complex zoning, and strict regulatory requirements—while maintaining reliability across diverse operating environments.

From main distribution panels and switchboards to sub-distribution and lighting panels, each component plays a defined role in managing power flow, protecting equipment, and ensuring safe operation. The effectiveness of a commercial electrical distribution system depends not only on correct component selection but also on thoughtful system design, protection coordination, and long-term scalability.

Understanding how these systems are structured, installed, and maintained is essential for ensuring safety, operational continuity, and compliance in modern commercial facilities.

Commercial electrical distribution encompasses the intricate network responsible for delivering electrical power efficiently and safely across various sectors such as office buildings, shopping centers, and industrial facilities.

At the core of this framework are commercial distribution panels, which serve as pivotal components within building electrical distribution systems.

Key functionalities include power distribution, circuit protection via circuit breakers and fuses, and load management to guarantee balanced and efficient energy flow. Components such as bus bars and residual current devices are integral, guaranteeing safety and compliance with regulatory standards.

This system's reliability mitigates electrical hazards and optimizes power delivery throughout the facility.

In commercial buildings, the distribution of power is a meticulously coordinated process that guarantees efficient and safe delivery of electricity from external sources to internal systems.

Commercial power distribution systems begin with electricity traveling through the power distribution grid at 13,800 volts, utilizing three-phase alternating current (AC) for minimal line loss. Transformers step down utility-level voltages to levels suitable for commercial distribution within the building.

Commercial electrical panels further divide and distribute electricity safely within the facility.

The core components of a commercial electrical distribution system encompass main distribution panels and switchboards, sub-distribution and lighting panels, as well as protection and control devices.

Main distribution panels serve as the pivotal node for receiving and distributing electricity from the primary power source, while sub-distribution panels extend power to specific areas to enhance load management.

Integral to system safety, protection, and control devices such as circuit breakers and residual current devices (RCDs) guarantee operational reliability and compliance with regulatory standards.

Essential infrastructure within commercial electrical systems, main distribution panels, and switchboards serve as the centralized hubs for control, protection, and isolation of electrical circuits.

These components are crucial in commercial electrical infrastructure, efficiently managing power distribution boards within low-voltage distribution systems. Their roles include:

Main distribution panels and switchboards are indispensable for ensuring operational continuity, enhancing safety, and maintaining regulatory compliance in commercial settings.

Sub-distribution and lighting panels function as essential components within commercial electrical distribution systems, facilitating the efficient allocation and control of electrical power.

These panels extend electricity from main distribution panels to specific zones, enabling precise load management and operational flexibility. Sub-distribution panels are employed to address zoning requirements, ensuring that power is effectively distributed across departmental boundaries. This segmentation allows for enhanced load balancing, consequently optimizing energy utilization within the facility.

Lighting panels, on the other hand, specialize in controlling commercial lighting circuits, contributing to energy efficiency and reducing operational costs. By isolating lighting systems, these panels facilitate dedicated management, minimizing disruptions across other electrical functions.

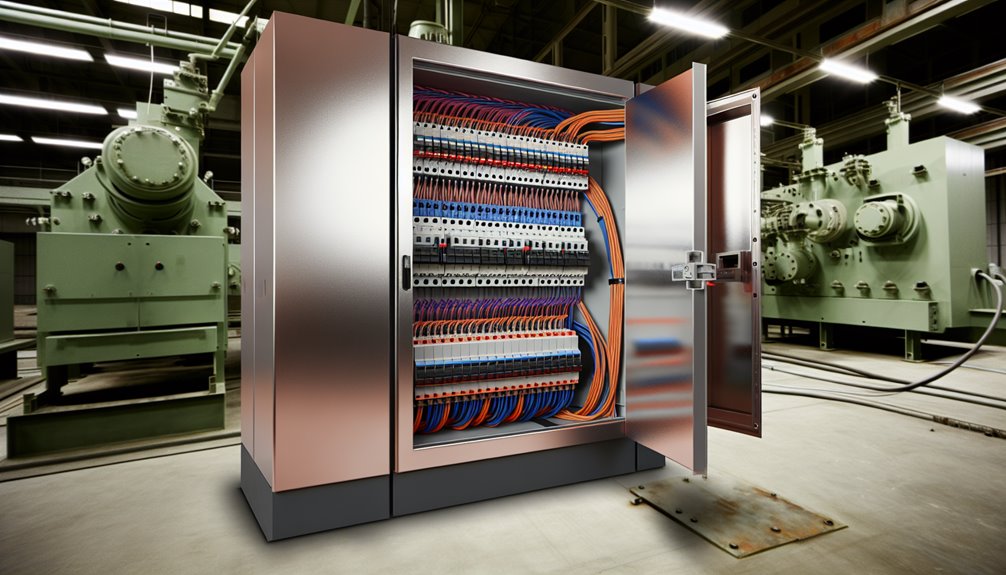

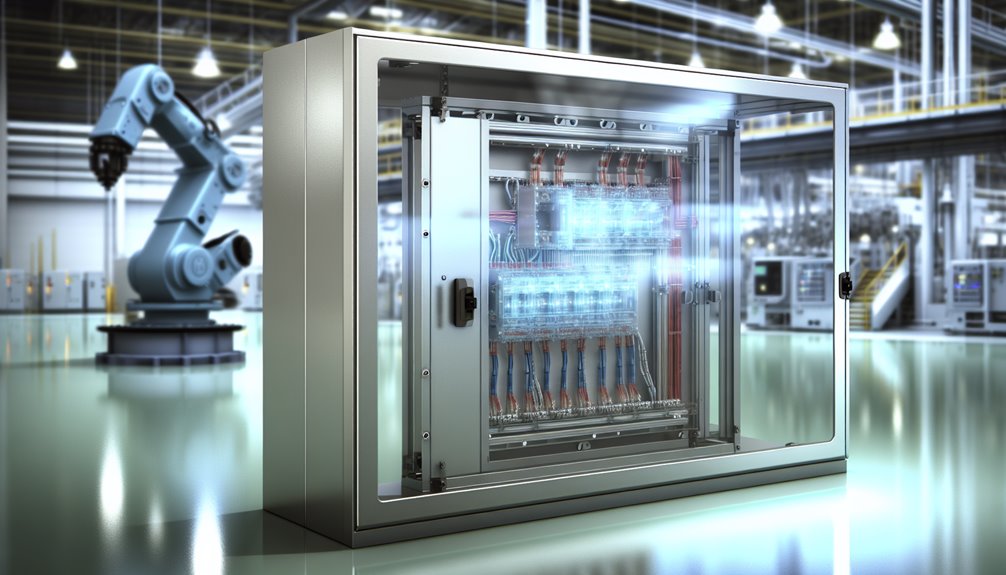

Custom-designed enclosures for these panels enhance their durability and adaptability to specific industrial environments.

Incorporating protection and control devices into commercial electrical distribution systems is essential for ensuring system integrity and operational safety. These components safeguard electrical systems by mitigating risks associated with faults and overloads.

Circuit breakers provide crucial overcurrent protection, automatically disconnecting the circuit to prevent damage. Residual Current Devices (RCDs) enhance safety by cutting off electricity during leakage events, thereby preventing electric shocks. Surge protection devices are important in shielding equipment from voltage spikes, ensuring system reliability.

Key benefits include:

Commercial distribution panels are critical in the structuring of electrical systems within large facilities, serving distinct functions based on their type.

Main Distribution Panels (MDP) act as the central conduit for power reception and onward distribution, while Sub-Distribution Panels (SDP) extend electrical reach to specific zones or departments, optimizing load management.

Lighting Distribution Boards (LDB) are specialized for managing lighting circuits, whereas motor and equipment panels are engineered to handle the operation and protection of electrical motors and associated machinery.

Main Distribution Panels (MDPs) serve as the crucial nodes in commercial electrical systems, where they receive high-voltage electricity from the main power source and effectively channel it into various smaller circuits.

MDPs guarantee seamless power distribution, essential for operational efficacy in commercial environments such as office buildings and industrial facilities. They encompass critical components:

Functioning as the primary power conduit, MDPs are indispensable in optimizing load management and guaranteeing compliance with electrical safety standards.

Following the operation of Main Distribution Panels (MDPs), Sub-Distribution Panels (SDPs) take on a pivotal role in the commercial electrical framework by efficiently extending electrical power to designated areas or departments within a facility. SDPs are essential for decentralizing the power distribution process, ensuring tailored power management and enhanced safety. Equipped with circuit breakers, bus bars, and residual current devices, SDPs maintain operational integrity by preventing overload and ensuring compliance with electrical regulations. Their strategic placement optimizes load balancing and minimizes electrical faults.

| Component | Function | Benefit |

|---|---|---|

| Circuit Breakers | Isolates power during faults | Enhances safety |

| Bus Bars | Distributes electricity evenly | Efficient power flow |

| RCDs | Cuts power during leakage | Prevents electrical shocks |

SDPs are indispensable for maintaining organized power flow in complex systems.

Lighting Distribution Boards (LDBs) play an essential role within commercial electrical infrastructure by providing dedicated control and distribution for lighting systems.

These panels guarantee that lighting circuits receive reliable power, maintaining ideal illumination levels throughout a facility. LDBs contribute to the overall efficiency and safety of a building’s electrical setup by incorporating specific components and protective mechanisms.

These features make LDBs essential in modern commercial settings.

Motor and equipment panels, integral components within commercial distribution systems, are specifically designed to manage and control electric motors and associated machinery.

These panels guarantee optimal operation by providing precise control over motor functions, enhancing both efficiency and safety. Equipped with circuit breakers, bus bars, and residual current devices, they offer robust protection against overloads and short circuits.

Such panels are essential for maintaining balanced electrical loads, preventing operational chaos, and reducing fire risks in industrial settings. Moreover, their role in load management assures that power is distributed evenly across circuits, maximizing performance and energy utilization.

As part of a broader distribution network, motor and equipment panels contribute considerably to the reliability and safety of electrical systems in industrial applications.

Commercial distribution panels play an essential role in various applications by guaranteeing efficient and safe power distribution across diverse building types.

These panels are integral to the electrical infrastructure of environments such as office buildings, retail centers, and complex mixed-use developments. Their deployment in data-driven commercial facilities underscores the critical need for reliable power management systems.

Integral to electrical infrastructure, these panels underscore the need for reliable power management in commercial facilities.

Key commercial applications include:

Through strategic implementation, these panels maintain operational continuity and safety compliance.

When approaching the design of commercial power distribution systems, several essential considerations must be meticulously analyzed to guarantee peak functionality and safety.

Electrical load calculation and diversity are paramount, making certain circuits are correctly sized and capable of handling varied demands without overstressing components.

Space allocation and accessibility are critical for maintenance and future expansion, allowing seamless integration of additional equipment.

Power quality and reliability must be maintained to prevent disruptions, protect sensitive electronics, and minimize downtime.

Integration with HVAC, lighting, and IT systems is also fundamental, necessitating a thorough approach to harmonize power distribution with building infrastructure.

Each factor requires detailed scrutiny to optimize operational efficiency, guarantee safety, and accommodate growth within the commercial environment.

The intricate task of designing commercial power distribution systems necessitates a stringent focus on safety, compliance, and adherence to established standards. These systems must align with IEC and NEC requirements to guarantee operational integrity and minimize downtime.

Integral to this process is the management of short-circuit ratings and fault protection, which are critical for preventing equipment damage and guaranteeing personnel safety. Additionally, effective earthing and grounding strategies are paramount, serving to stabilize voltage levels and protect against surges.

Understanding the intricacies of installation and maintenance best practices is essential for optimizing the performance and longevity of commercial electrical distribution panels. Proper panel placement is vital, ensuring adequate clearance for safe operation and maintenance access.

Adherence to labelling standards enhances operational efficiency, providing clear identification of circuits and components. Thorough documentation supports systematic troubleshooting and future upgrades.

Enhancing operational efficiency through proper labelling and thorough documentation aids in troubleshooting and seamless future upgrades.

Regular inspection, testing, and preventive maintenance are imperative to detect wear, corrosion, or loose connections, thereby averting potential failures. Load testing should be conducted to ascertain balanced circuitry, preventing overloads.

Panel cleaning is necessary to mitigate overheating risks. Prompt resolution of any identified issues is advised to preclude costly downtime and maintain the panel's operational integrity.

Optimizing the performance and longevity of commercial electrical distribution panels involves understanding the indicators that signal the need for system upgrades.

Frequent circuit breaker trips or power outages signify an overloaded system unable to meet modern demands. Flickering or dimming lights indicate voltage fluctuations, which can lead to hazardous conditions. Rising energy bills without increased usage highlight inefficiencies, often due to outdated components or poor wiring.

Equipment malfunctions or frequent repairs are symptomatic of unstable voltage or suboptimal power quality. Recognizing these signs facilitates timely upgrades, integrating advanced technologies like modern MCBs and RCBOs to enhance safety and efficiency.

Additionally, systems over 20 years old often lack compliance with contemporary standards, compelling the adoption of energy-efficient solutions and modern protective measures.

As the commercial electrical distribution landscape evolves, energy efficiency and smart integration become paramount.

In 2025, LED lighting standards and smart systems featuring sensors and automation are foundational. Retrofits in older structures enhance energy efficiency, driven by thorough energy audits identifying waste.

Backup power solutions gain prominence with investments in UPS, generators, and battery storage systems critical for data centers and healthcare.

Smart building integration mandates seamless communication across electrical, lighting, HVAC, and access control systems, necessitating electricians skilled in networked environments.

Rapid, reliable service becomes non-negotiable, as operational downtime affects revenue and safety.

Firms like Bates Electric, providing 24/7 support, continue to maintain compliance and operational continuity, positioned at the forefront of these evolving demands.

Commercial electrical distribution systems are designed to handle higher electrical loads, three-phase power, and more complex circuit layouts than residential systems. They also require stricter safety controls, coordinated protection devices, and compliance with commercial and industrial electrical standards to support continuous operation and diverse equipment demands.

Three-phase power provides more stable and efficient energy delivery for large electrical loads such as HVAC systems, elevators, motors, and commercial machinery. It reduces current per phase, minimizes voltage drop, and improves overall system efficiency compared to single-phase power commonly used in residential buildings.

Distribution panels act as control and protection points within a commercial electrical distribution system. They divide incoming power into branch circuits, protect equipment through breakers and protective devices, and allow for load balancing across different zones or functions within the building.

Load management is achieved through proper circuit design, load diversity calculations, and the strategic placement of main and sub-distribution panels. This ensures electrical demand is evenly distributed, prevents overload conditions, and allows systems to operate efficiently during peak usage periods.

Upgrades are typically required when electrical demand increases, equipment changes, or compliance standards evolve. Common indicators include frequent breaker trips, voltage instability, limited panel capacity, difficulty adding new circuits, or systems that no longer meet current electrical codes.

Commercial electrical distribution systems form the backbone of safe and reliable power delivery in modern commercial buildings. From incoming utility connections to final branch circuits, each layer of the distribution network must be carefully designed to manage load demand, protect equipment, and comply with evolving safety standards.

As buildings grow more complex and power requirements increase, effective distribution planning—supported by properly rated panels, coordinated protection devices, and durable enclosures—becomes critical to long-term performance and operational continuity. A well-executed commercial electrical distribution system not only reduces risk and downtime but also provides the flexibility needed to adapt to future expansion and technological change.

If you are planning a new project or upgrading an existing system, contact Conya to discuss distribution panels and enclosure solutions tailored to your application, compliance requirements, and long-term operating conditions.