Selecting a low-voltage switchgear manufacturer shapes safety, uptime, and total cost of ownership. Global brands tout digital diagnostics, modular designs, and rigorous compliance, while regional suppliers promise agility and tailored support. The stakes rise with electrification, data centers, and sustainability mandates. Yet price parity can mask differences in engineering depth, lifecycle services, and cyber-hardening. Understanding who leads in 2025—and why—clarifies the risk-reward tradeoff and informs the next procurement decision.

Selecting the right low-voltage switchgear manufacturer is more than a purchasing decision—it’s a strategic investment in the safety, efficiency, and reliability of your electrical infrastructure. For organizations managing industrial facilities, data centers, commercial buildings, or renewable energy projects, the manufacturer behind the equipment plays a critical role in long-term performance.

In short, the choice of manufacturer directly influences operational safety, efficiency, and long-term profitability. Businesses that prioritize these factors when evaluating suppliers set themselves up for greater resilience and growth.

When sourcing low voltage switchgear, one of the most important choices is whether to partner with a global supplier or a regional manufacturer. Both options bring clear advantages, and the right decision often depends on the scale of your operations, project complexity, and long-term goals.

Global manufacturers—such as ABB, Siemens, Schneider Electric, Eaton, and Mitsubishi—are widely recognized for their breadth of product lines, international certifications, and proven track records across multiple industries. For organizations managing projects in different countries or requiring the latest innovations in digital monitoring, energy efficiency, or smart automation, a global supplier can feel like the safest choice.

However, this scale often comes with trade-offs. Global suppliers may have higher upfront costs, longer lead times, and more standardized offerings that leave less room for project-specific customization.

Regional and specialized manufacturers provide a different type of value. They are often more flexible, more willing to engineer tailored solutions, and able to offer faster support throughout a project’s lifecycle. Pricing can also be more competitive, particularly when regional suppliers source locally and design with market-specific standards in mind.

Still, regional players may not always have the global footprint, R&D resources, or expansive service networks of multinational corporations. That’s why, at Conya, we’ve built our approach around combining the adaptability of a regional supplier with the quality, certifications, and global readiness that international buyers demand.

Ultimately, the choice isn’t about global vs regional, but about selecting a partner that aligns with your project requirements, operational goals, and long-term growth strategy.

If you’re seeking a manufacturer that bridges local agility with international standards, we’d be glad to discuss how Conya can support your next project.

Choosing a low-voltage switchgear manufacturer isn’t just about comparing product catalogs — it’s about selecting a partner you can trust with the safety, efficiency, and long-term performance of your electrical systems. In 2025, the market continues to be shaped by both global giants and specialized regional players, each offering distinct advantages for different project needs.

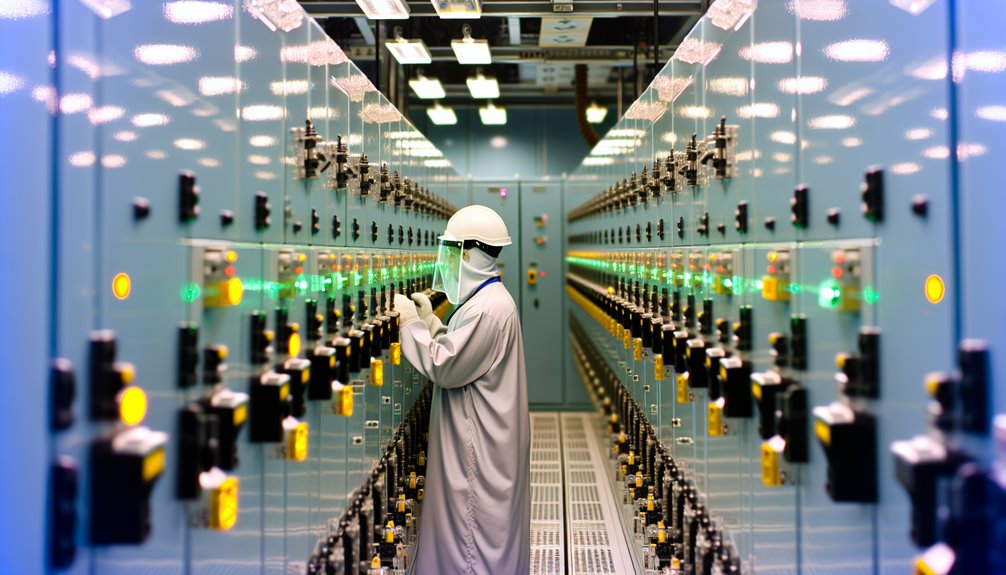

Source: global.abb/group/en

ABB has long been a leader in electrification and automation, delivering reliable, high-performance low-voltage switchgear to industries worldwide. Their systems are engineered for uptime, protection, and precise control, supporting critical environments such as industrial plants, data centers, and infrastructure projects. ABB’s solutions emphasize modular expansion, digital diagnostics, and condition-based service, giving operators confidence in predictable operation and simplified lifecycle management.

Source: www.mitsubishielectric.com/en/

Mitsubishi Electric brings proven reliability and modern intelligence to low-voltage switchgear. Their systems deliver actionable data, optimized energy use, and enhanced operational insight, allowing operators to maintain safety standards while improving uptime. With modular architectures and intuitive interfaces, Mitsubishi Electric’s solutions offer scalable performance across industrial, commercial, and public sector applications worldwide.

Source: www.siemens.com/global/en.html

Siemens continues to anchor the low-voltage switchgear market with solutions that combine scalability, intelligence, and safety. Their platforms enable precise load management, selective coordination, and transparent maintenance planning. SIVACON S8 and SENTRON systems are ideal for mission-critical environments, giving engineers and operators confidence in both performance and long-term adaptability, while supporting sustainability and energy-efficiency initiatives.

Source: www.eaton.com/ie/en-gb.html

Eaton focuses on pragmatic, field-proven low-voltage switchgear designed to maximize uptime and scalability across industrial, infrastructure, and power projects. Their systems provide predictable maintenance windows, controlled fault response, and modular expansion capabilities, helping operators manage risk while reducing operational interruptions. Eaton’s presence in over 175 countries ensures standardized spares, global compliance, and consistent lifecycle support, making it a reliable partner for large-scale, complex projects.

Source: www.toshibafoundation.com/index.html

Toshiba delivers disciplined, engineering-first low-voltage switchgear suitable for industrial and infrastructure applications. Their systems prioritize predictable control, robust isolation, and reliable protection, which is especially important in uptime-sensitive environments. With a focus on compact designs, clear maintenance access, and international compliance, Toshiba enables operators to streamline lifecycle service and confidently scale their power distribution networks across multiple regions.

Source: www.hitachi.com/en/

Hitachi integrates innovation and efficiency into low-voltage switchgear solutions, providing dependable protection and control for modern distribution networks. Their products enable rapid fault clearing, scalable risk mitigation, and clear maintenance boundaries, helping engineers maintain uptime and operational reliability. With a focus on rigorous testing and robust lifecycle support across Asia and North America, Hitachi’s switchgear offers consistent performance even under demanding conditions, making it a trusted option for global operators.

Source: www.se.com/ww/en/

Schneider Electric pairs robust low-voltage switchgear with digital intelligence and sustainability initiatives. Their Masterpact and Compact NSX systems provide precise protection, scalable architectures, and lifecycle management capabilities, helping operators minimize unplanned outages and optimize load profiles. Operating in over 100 countries, Schneider delivers standardized, configurable solutions that align with modern energy and compliance requirements, making it a trusted partner for global and regional projects alike.

Source: www.rockwellautomation.com/en-us.html

Rockwell Automation focuses on power distribution integrated with plant-wide control strategies. Their Allen-Bradley switchgear enables deterministic performance, predictive maintenance, and unified operational oversight, reducing downtime and improving safety. Designed for North American and international markets, Rockwell’s systems emphasize interoperability with drives, PLCs, and MCCs, providing engineers with actionable insights and consistent operational behavior from feeder to field.

Source: www.larsentoubro.com

Larsen & Toubro delivers engineering-led reliability in low-voltage switchgear, combining durable mechanics with intelligent monitoring. Their switchboards and panels emphasize precise risk management, fault isolation, and scalable architectures, making them suitable for utilities, data centers, and heavy industrial applications. With a strong domestic base and growing international presence, L&T ensures consistent lead times, lifecycle support, and configurable solutions tailored to project-specific needs.

Source: www.weg.net/institutional/US/en/

WEG combines deep motor expertise with a broad protection and control portfolio, delivering low-voltage switchgear that meets international standards and supports diverse industrial applications. Their solutions focus on precise protection, predictable maintenance windows, and operator safety, helping engineers and operators manage risk confidently. With a presence in over 140 countries, WEG balances local engineering knowledge with global support, enabling scalable and reliable power distribution worldwide.

Source: cnconya.com

Conya has built a reputation over three decades as a trusted low-voltage switchgear manufacturer, combining certified quality with adaptable solutions for diverse projects. Our systems prioritize safety, reliability, and intelligent power distribution, supporting rail transit, municipal facilities, buildings, and emerging energy storage applications.

By partnering with global brands like ABB, Eaton, and AEG, Conya ensures component availability, compliance, and consistent performance, while our engineering support, technical training, and maintenance plans help clients select the right voltage ranges, architectures, and protection schemes to meet precise operational goals.

Source: www.afswitchgear.co.uk

AF Switchgear specializes in custom-engineered low-voltage switchgear designed for control, safety, and uptime-critical applications. Their solutions serve data centers, healthcare, and transportation sectors, combining modular expansion, factory acceptance testing, and metering/control integration. With certified busbar systems and documented protection settings, AF Switchgear enables operators to maintain high reliability, phased expansion, and compliance across demanding projects.

Source: www.bowerselec.co.uk

Bowers Electricals brings over 70 years of experience to the low-voltage switchgear market, offering a blend of new and expertly refurbished equipment with full lifecycle services. Their portfolio enables specifiers to balance budget, lead time, and performance, while in-house rewinding and refurbishment extend asset life without compromising compliance. Through structured site surveys, design input, installation, testing, and emergency response, Bowers delivers predictable uptime and disciplined power distribution upgrades for industrial, commercial, and infrastructure projects.

Source: slaters-electricals.com

Slaters Electricals stands out for its extensive stock and turnkey service offerings, enabling rapid project delivery and flexible power distribution solutions. Their systems provide predictable timelines, controlled configurations, and cost management, while supporting upgrades across current and legacy switchgear. With factory-tested assemblies, documented traceability, and solutions tailored to outage windows and expansion paths, Slaters delivers scalable, standards-aligned outcomes for facilities managers, contractors, and specifiers.

Source: www.tesgroup.com

TES Group specializes in engineered switchgear for data centers, banks, hospitals, and premium commercial offices, prioritizing uptime, safety, and maintainability. Their solutions integrate intelligent protection coordination and granular power monitoring, allowing operators precise control over loads and fault response. Rigorous factory acceptance testing, scalable configurations, and sustainable materials make TES Group a trusted partner for mission-critical and high-performance infrastructure projects.

Source: www.iemfg.com

IEM is North America’s largest independent full-line producer of electrical distribution and control systems, delivering custom low-voltage switchgear tailored to complex projects. Their engineered approach ensures granular protection, coordinated fault response, and reliable monitoring, aligning with strict uptime and performance requirements in technology, manufacturing, and utility sectors. With scalable, factory-tested solutions optimized for installation and commissioning, IEM provides precise, project-specific power distribution without compromising schedule or compliance.

Source: www.gkexpertise.com

GK Expertise, based in Chennai, India, delivers LV/HV switchgear, engineered control panels, and numerical relays for power protection and automation. Its portfolio targets deterministic performance, clear protection selectivity, and repeatable commissioning outcomes.

The company supports industrial, utility, and infrastructure projects with configurable architectures aligned to IEC standards and robust documentation for auditability.

Emphasis on gk innovation is evident in digitally supervised protection schemes, event logging, and predictive diagnostics that shorten fault isolation times. Numerical relays integrate seamlessly with SCADA, enabling parameterization, remote interrogation, and version-controlled settings management.

Switchgear assemblies are engineered for arc-fault containment, thermal stability, and maintainable segregation to reduce downtime.

Through GK sustainability, designs prioritize lifecycle efficiency—optimized copper utilization, low-loss components, and retrofit pathways—ensuring measurable reliability, maintainability, and cost control across evolving loads and expansions.

Source: www.btechswitchgear.ae

Btech Switchgear provides high-quality, modular low-voltage switchgear across the Middle East, designed for industrial campuses, infrastructure, and advanced building systems. Their solutions enable phased expansion, stable multi-source operation, and energy efficiency, with factory-tested assemblies and SCADA-ready interfaces. Btech emphasizes reliability, compliance, and configurable protection, giving operators confidence in continuous uptime and scalable capacity.

Source: dohoelectric.com

DOHO focuses on engineered low-voltage switchgear tailored to project requirements in manufacturing, infrastructure, and energy sectors. Their modular designs support phased expansion, while standardized components and accessible compartments simplify maintenance. With emphasis on compliance, fault isolation, and predictable lifecycle costs, DOHO delivers switchgear solutions that minimize downtime and support smooth project execution.

Source: keeya.com.cn

Keeya specializes in tailored low-voltage switchgear designed around application demands and compliance standards. Their products offer precise control, scalable capacity, and predictable maintenance windows across residential, commercial, and industrial deployments. With integrated protection, metering, and SCADA-ready interfaces, Keeya provides engineered solutions that simplify operations and support long-term reliability.

The low-voltage switchgear industry in 2025 is evolving rapidly, shaped by technology, regulation, and shifting customer expectations. Staying ahead of these developments helps decision-makers protect investments and prepare for the future.

IoT-enabled monitoring and predictive analytics are transforming switchgear from basic protection devices into intelligent energy management systems. Smart solutions enable real-time visibility, remote diagnostics, and condition-based maintenance, helping operators minimize downtime and improve operational efficiency.

Global sustainability goals are influencing design priorities. Manufacturers are phasing out SF₆ insulation, adopting recyclable materials, and introducing low-loss components to support carbon-reduction targets. According to IMARC Group, demand for greener designs is accelerating along with the integration of renewables and smart grid technologies, which is driving manufacturers to develop low-voltage switchgear capable of handling variable loads safely.

With urbanization and denser industrial facilities, space-saving solutions are in demand. Modular and prefabricated switchgear systems are gaining popularity for their ease of installation, flexibility, and scalability—allowing facilities to expand or upgrade without major disruptions.

Stricter international standards are setting higher expectations for manufacturers. Advanced arc-flash protection, selective fault isolation, and robust fault detection are increasingly standard, particularly in mission-critical environments such as data centers, hospitals, and heavy industry.

The global low-voltage switchgear market is projected to exceed USD 84 billion by 2032 (SNS Insider). Growth is especially strong in Asia-Pacific, the Middle East, and Africa, where large-scale infrastructure projects and electrification efforts are accelerating adoption.

Selecting the right low-voltage switchgear manufacturer is more than a procurement decision—it directly impacts the reliability, safety, and scalability of your operations. Here are the key factors to guide your choice:

Every facility has unique energy requirements. Begin by clearly defining your daily power consumption, peak loads, and operational demands. This ensures you select switchgear that matches your specifications and supports seamless integration with your existing infrastructure.

Switchgear is a long-term investment. Assess the materials, construction standards, and manufacturing quality to ensure reliability and longevity. Look for compliance with internationally recognized standards such as UL, IEC, or CE, which indicate rigorous testing and adherence to quality benchmarks.

Electrical safety is non-negotiable. Confirm that the manufacturer’s products meet or exceed relevant safety standards to protect personnel and equipment. Features such as arc-flash mitigation, fault isolation, and secure enclosure design are critical for maintaining safe operations.

Consider both upfront costs and lifecycle value. High-quality switchgear may have a higher initial price but reduces maintenance requirements, downtime, and energy losses over time, ultimately providing better return on investment.

Anticipate your facility’s growth. Choose switchgear that allows for modular expansion, system upgrades, or integration with smart monitoring solutions. This flexibility ensures your electrical infrastructure can evolve alongside your operational needs.

Modern switchgear should support energy optimization. Efficient components, low-loss designs, and power-factor improvement capabilities can help reduce operating costs and improve overall energy performance.

By systematically evaluating these factors, decision-makers can select a manufacturer that not only meets current operational requirements but also supports long-term reliability, safety, and scalability for their power distribution systems.

Custom units typically have longer lead times—often weeks to months—due to engineering, testing, and approvals. Standard switchgear availability is faster, sometimes stock. Custom switchgear advantages justify delays when precise specifications, integration, and resilience matter to operators seeking stringent control and predictable performance.

He notes required certifications depend on destination: CE/UKCA, IEC/UL compliance, RoHS/REACH, and often CCC, EAC, or CB Scheme. Export regulations dictate documentation from certification agencies, plus test reports, country-of-origin, HS codes, and verified conformity assessment bodies.

Arc-flash risk is assessed via arc flash analysis: calculating incident energy, labeling boundaries, and PPE levels. Design considerations include fault current limitation, selective coordination, protective device settings, arc-resistant gear, remote racking, maintenance modes, and documented verification to enforce control and compliance.

They enforce network encryption and secure protocols; they harden devices, yet they segment networks. They deploy MFA, but they also whitelist. They monitor anomalies continuously while patching promptly. They manage certificates centrally and log immutably for forensics and control.

They guarantee post-discontinuation support via last-time-buy windows, obsolescence notices, and stocked spare parts aligned to the product lifecycle. Cross-referenced equivalents, repair/refurbish programs, and documented change control give planners predictable availability, minimizing downtime and preserving configuration control for critical installations.

Choosing the right low-voltage switchgear manufacturer is a critical decision that shapes the reliability, safety, and efficiency of your operations. Both global leaders and regional specialists bring innovation, compliance, and lifecycle support to the table, but selecting the right partner requires careful evaluation.

By considering factors such as engineering quality, certifications, customization options, technical support, and total cost of ownership, decision-makers can ensure power distribution systems that are safe, scalable, and resilient.

At Conya, we combine decades of manufacturing experience with intelligent, reliable low-voltage switchgear solutions. Our modular designs, energy-efficient components, and comprehensive lifecycle support help operators worldwide maintain uptime, reduce risk, and achieve long-term operational excellence.

Ready to optimize your power distribution? Contact us today to explore tailored low-voltage switchgear solutions that meet your facility’s specific needs.