Custom electrical enclosures are engineered to meet specific operational needs, providing tailored solutions for industries such as automation, renewable energy, and power distribution. These enclosures accommodate unique requirements like cooling systems and enhanced security, ensuring compliance with strict standards. Various materials are chosen to withstand challenging environments, enhancing durability. The distinction between custom and off-the-shelf options raises questions about cost-effectiveness and specification precision. What factors dictate the ideal choice for complex applications?

Defining a "custom" electrical enclosure, it involves a thorough approach to tailoring specific aspects such as dimensions, layout, materials, compliance, and functional integration to the unique requirements of a project.

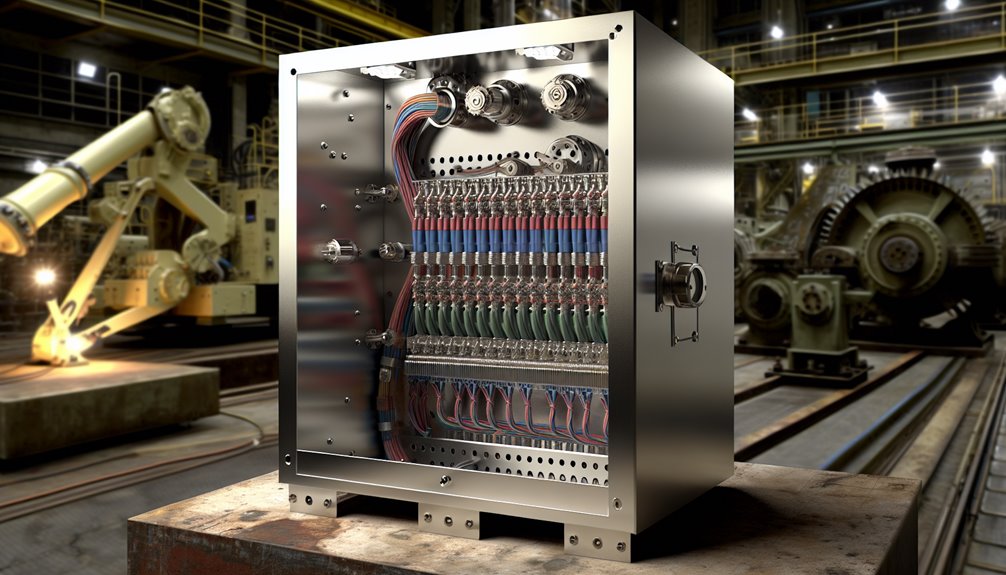

Custom electrical enclosures are engineered beyond off-the-shelf solutions, emphasizing precise dimensional accuracy and ideal layout configurations. A custom enclosure manufacturer is pivotal in meeting stringent project specifications by offering diverse customization options, such as custom metal enclosure designs that incorporate specialized cutouts and mounting provisions.

Material selection plays a critical role, with choices ranging from stainless steel to aluminum, ensuring robustness and environmental resilience. Compliance with industry standards is paramount, necessitating extensive design assessments.

Functional integration is achieved through meticulous engineering, aligning enclosure features with operational demands for seamless system compatibility.

Custom electrical enclosures are essential in a variety of demanding scenarios, particularly where standard solutions fall short due to specific environmental or operational requirements.

In industrial automation and control systems, a custom industrial electrical enclosure guarantees the housing meets precise specifications for ideal integration and protection.

Power distribution and utilities benefit from NEMA electrical enclosures that safeguard against environmental variables and unauthorized access.

Renewable energy applications, such as solar and wind installations, often require outdoor electrical enclosures that withstand harsh weather conditions.

OEM equipment and machinery demand bespoke designs for seamless component fit and function.

Finally, environments subject to corrosive elements necessitate enclosures with custom coatings and materials to prevent degradation, guaranteeing longevity and reliability in challenging conditions.

Material selection for custom electrical enclosures requires a thorough understanding of the environmental conditions and performance requirements.

Steel, stainless steel, and aluminum offer varied benefits such as durability, corrosion resistance, and weight efficiency, which are critical for different industrial applications.

Non-metallic and composite enclosures provide alternative solutions with enhanced chemical resistance and electrical insulation properties, making them suitable for specific regulatory and operational demands.

Although choosing the right material for custom electrical enclosures can be complex, understanding the unique properties of steel, stainless steel, and aluminum is vital.

Steel offers robust strength, making it an ideal choice for custom control panel enclosures that demand durability. Its cost-effectiveness is a significant advantage in electrical enclosure fabrication.

Conversely, stainless steel electrical enclosures provide superior corrosion resistance, essential for harsh environments, albeit at a higher cost.

Aluminum, known for its lightweight nature, offers a prime balance between strength and weight, reducing overall structural load while maintaining resilience.

Each material presents distinct trade-offs regarding strength, corrosion resistance, weight, and cost, necessitating a meticulous evaluation to guarantee the custom enclosure aligns with specific application requirements.

After evaluating the strengths and limitations of metallic materials like steel, stainless steel, and aluminum for custom electrical enclosures, attention turns to the non-metallic and composite alternatives.

These materials offer distinct advantages, particularly regarding weight, corrosion resistance, and electrical insulation.

Particularly, fiberglass and polycarbonate emerge as premier choices for weatherproof electrical enclosures.

Such options extend the versatility of enclosures across varied industrial applications.

In the domain of custom electrical enclosures, adherence to specific standards and ratings is essential for ensuring safety and functionality.

NEMA and IP ratings provide detailed criteria for protection against environmental factors such as dust and moisture, while UL and IEC certifications address overall safety and performance specifications.

For applications in hazardous areas, compliance with stringent regulatory requirements is necessary to mitigate risks associated with explosive atmospheres and other potential dangers.

Understanding the nuances of NEMA and IP ratings is imperative for ensuring compliance and ideal protection of electrical enclosures. These ratings determine the environmental suitability and protection level of enclosures, pivotal for safeguarding sensitive electronic components.

An analytical approach to these ratings prevents over-specification, optimizing cost and function.

While traversing the complex landscape of industrial certifications, adherence to UL (Underwriters Laboratories), IEC (International Electrotechnical Commission), and hazardous area requirements is vital for guaranteeing both safety and compliance in diverse applications.

UL certification focuses on product safety standards for electrical enclosures, emphasizing rigorous testing for fire, shock, and mechanical hazards.

IEC standards, on the other hand, facilitate global interoperability by defining international safety, performance, and environmental criteria.

Hazardous area requirements, often governed by ATEX or IECEx frameworks, are essential for enclosures in volatile environments, dictating design specifications to prevent ignition in explosive atmospheres.

Compliance with these certifications guarantees that electrical enclosures meet stringent safety and functional benchmarks, thereby safeguarding equipment and personnel in critical operational contexts.

Custom electrical enclosures incorporate a range of design features that cater to varied functional requirements. These features are meticulously crafted to meet specific operational demands while ensuring peak performance.

The process of designing custom electrical enclosures begins with a thorough requirement definition and engineering review to ascertain alignment with project specifications and standards.

This is followed by the design, fabrication, and finishing phases, where precise dimensions and specialized features are implemented using advanced sheet metal fabrication techniques.

Rigorous inspection and testing are conducted before the final delivery to warrant compliance and performance under specified conditions.

Initiating the custom electrical enclosure design process necessitates a thorough requirement definition and engineering review, which serves as the cornerstone for successful project execution.

This phase involves a meticulous evaluation of site conditions, load requirements, and compliance needs. An analytical approach guarantees all variables are accounted for, empowering clients to maintain control over the process.

Key components of this stage include:

This structured approach ensures a robust foundation for the subsequent phases of the custom enclosure design journey.

Initiating the custom electrical enclosure design process involves a sequence of meticulously coordinated steps that guarantee precision and functionality.

It begins with a sophisticated CAD design phase where detailed schematics are generated to outline exact specifications.

Precision cutting techniques follow, utilizing state-of-the-art machinery to shape metal components with unparalleled accuracy.

Welding forms the structural integrity of the enclosure, securing robust connections capable of enduring operational stresses.

The coating stage introduces protective layers, enhancing resistance to environmental factors and assuring compliance with industry standards.

The assembly phase meticulously integrates all components, resulting in a cohesive and functional enclosure.

Each step is executed with rigorous quality control measures to confirm the enclosure meets the precise requirements and standards set forth during the design phase.

Guaranteeing rigorous quality standards, inspection and testing serve as critical components in the custom electrical enclosure design process. The thorough evaluation framework guarantees that each enclosure meets stringent specifications and compliance mandates.

Precision testing and documentation prepare the enclosure for real-world applications, optimizing its performance and reliability. Key elements include:

This meticulous process ensures that custom enclosures are delivered with precision and reliability.

Although off-the-shelf electrical enclosures offer convenience and immediate availability, custom enclosures provide a distinct advantage regarding long-term performance and specific application suitability.

Tailored designs guarantee precise dimensional fit and integration with existing systems, enhancing operational efficiency. Customization allows for specific material selection, guaranteeing peak protection against environmental factors and compliance with stringent industry standards.

Additionally, custom enclosures offer flexibility in incorporating specialized features such as unique access points, cutouts, and finishing options. This customization is vital for applications requiring high reliability and durability, where off-the-shelf solutions may fall short.

Furthermore, the inclusion of bespoke branding and aesthetic enhancements enhances product identity. Consequently, for demanding environments, custom enclosures deliver unparalleled performance and longevity, surpassing generic alternatives.

When considering the shift from off-the-shelf enclosures to custom solutions, cost factors become a pivotal aspect of decision-making. A multitude of variables intricately influence pricing.

Understanding these critical factors allows stakeholders to make informed decisions, optimizing expenditure while achieving tailored enclosure solutions.

Even well-intentioned enclosure specifications can create long-term operational problems if key practical factors are overlooked. The most common mistakes tend to fall into four areas: access, thermal performance, protection ratings, and future scalability.

Failing to account for installation and maintenance access often results in enclosures that are difficult to service once installed. Limited door swing, poor internal layout, or inaccessible terminals can significantly increase downtime and labour costs over the equipment’s lifecycle.

Thermal planning is another frequent weak point. Specifying an enclosure without properly evaluating internal heat load, ambient temperature, or airflow can lead to overheating, premature component failure, and derated performance—issues that are costly to correct after commissioning.

Over-specifying IP or environmental ratings is also common. While higher ratings may appear safer on paper, they often increase material, sealing, and manufacturing costs without delivering meaningful benefits for the actual operating environment.

Finally, many projects fail to plan for future expansion. Enclosures designed with no spare space, no allowance for additional cable entries, or no modular flexibility often require complete replacement when systems are upgraded.

| Mistake | Impact on the Project | Better Practice |

|---|---|---|

| Ignoring access requirements | Difficult maintenance, longer downtime | Design for safe and practical service access |

| Inadequate thermal planning | Overheating, reduced component lifespan | Calculate heat load and integrate cooling early |

| Overengineering protection ratings | Higher cost with no functional gain | Match IP rating to real site conditions |

| No allowance for future expansion | Costly retrofits or enclosure replacement | Include spare space and scalable layouts |

Avoiding these pitfalls at the specification stage helps ensure that custom electrical enclosures remain cost-effective, serviceable, and adaptable throughout their operational life—rather than becoming a constraint after installation.

Avoiding common specification mistakes is only part of the equation. Achieving a successful custom electrical enclosure also depends on how effectively you collaborate with the manufacturer throughout the design and production process. Clear alignment early on reduces revisions, controls costs, and ensures the final enclosure performs as intended in real operating conditions.

Several practical collaboration principles consistently lead to better outcomes:

Define all technical requirements in detail from the outset. This includes enclosure dimensions, materials, ingress protection levels, mounting methods, internal layouts, and environmental conditions such as temperature, humidity, and exposure to dust or chemicals. Clear documentation minimises assumptions and prevents costly design changes later.

Supplying complete and up-to-date CAD drawings allows the manufacturer to interpret your requirements correctly and manufacture with precision. Well-prepared drawings reduce fabrication errors, improve dimensional accuracy, and speed up the approval process.

Engaging in design reviews ensures that enclosure construction, component placement, thermal management, and access points align with operational needs and applicable standards. Early feedback during this stage is far more efficient than corrections after production has begun.

Establish clear communication channels and decision points from the start. Defined responsibilities, regular progress updates, and documented change approvals improve transparency and keep the project on schedule.

When these practices are followed, collaboration shifts from a transactional relationship to a technical partnership. The result is a custom enclosure that meets performance requirements, supports long-term maintenance, and integrates smoothly into the wider electrical system—without unnecessary delays or redesigns.

Typical lead time for custom electrical enclosures ranges from six to eight weeks. This period encompasses design assessment, approval processes, and advanced manufacturing techniques, ensuring precise alignment with specified requirements. Each phase meticulously adheres to quality and certification standards.

Ironically, guaranteeing environmental protection for custom enclosures involves not just understanding IP ratings, but also evaluating material resilience, seal integrity, and proper ventilation. Consulting engineers for tailored specifications guarantees performance exceeds mere compliance, offering unparalleled control.

Yes, specifying a particular brand of locking mechanism is acceptable. Clients can coordinate with the engineering team to incorporate precise specifications, ensuring alignment with security, durability, and compatibility requirements for their custom enclosure solutions.

Branding integration on enclosures is a veritable symphony of customization, allowing logos via silk-screening, etching, or anodizing. This meticulous process guarantees unparalleled consistency and precision, providing industry professionals with unparalleled control over their enclosure's aesthetic identity.

Custom enclosures manage extreme temperature variations through advanced insulation materials and climate-control features. Precision-engineered designs, such as ventilation louvering and heat-dissipating finishes, guarantee robust thermal regulation, enhancing operational reliability and extending equipment lifespan in diverse environmental conditions.

In the domain of electrical enclosures, the contrast between custom and off-the-shelf solutions underscores a fundamental trade-off between general availability and application-specific performance. Custom enclosures—engineered with tailored materials, precise structural design, and strict compliance alignment—offer a level of protection and integration that standard alternatives rarely achieve. While this approach may involve higher upfront investment, it delivers long-term value through improved reliability, serviceability, and system longevity in demanding industrial environments.

For projects where operating conditions, compliance requirements, or future scalability cannot be compromised, working with an experienced manufacturer becomes essential. Conya Electric supports this process by combining custom enclosure design, manufacturing expertise, and standards-driven engineering to help ensure that each solution fits its application—not the other way around.

Work with Conya to develop custom electrical enclosures designed for your application, environment, and long-term performance requirements.