Selecting between indoor and outdoor distribution boxes starts with the environment and compliance. Indoor units are suited for controlled spaces with low moisture and particulates, often rated IP20–IP40, while outdoor enclosures require IP65–IP68 or NEMA 3R/4/4X ratings to resist rain, dust, and corrosion. Material choice, locking hardware, gasket design, and thermal management affect longevity and safety. Sizing for future circuits prevents costly retrofits. The differences extend beyond ratings, influencing reliability, maintenance intervals, and total ownership costs.

Because the installation environment dictates exposure, hazard profiles, and service life, indoor and outdoor distribution boxes are engineered with different protection, materials, and certifications.

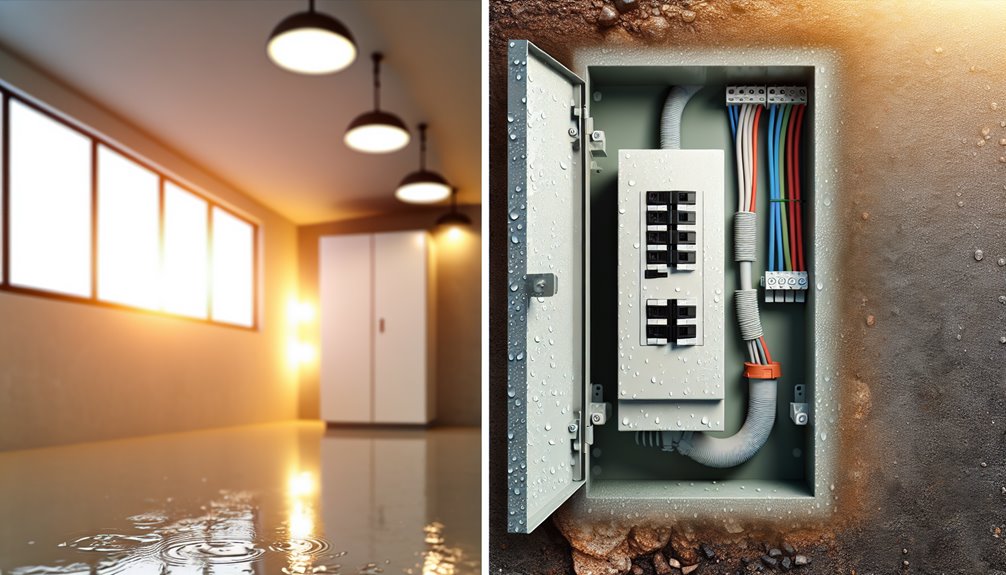

Exposure risk drives requirements: indoor vs outdoor distribution box selection hinges on moisture, particulates, UV, and impact. Outdoor sites demand a weatherproof distribution box with sealed gaskets, corrosion-resistant alloys or FRP, UV-stable polymers, and validated ingress protection.

Outdoor distribution boxes require sealed, UV-stable, corrosion-resistant enclosures with validated ingress protection against moisture, dust, and impact.

Safety responsibility escalates outdoors due to public access and conducive wet conditions; NEMA enclosure ratings (e.g., Type 3/3R/4/4X) and corresponding IP65–IP68 targets quantify barriers against rain, hose-down, and submersion.

Long-term reliability expectations diverge: outdoor assets must survive thermal cycling, hail, and salt fog without maintenance drift, while indoor units prioritize compact form, fire performance, and controlled thermal management within IP20–IP54 and NEMA Type 1/12 envelopes.

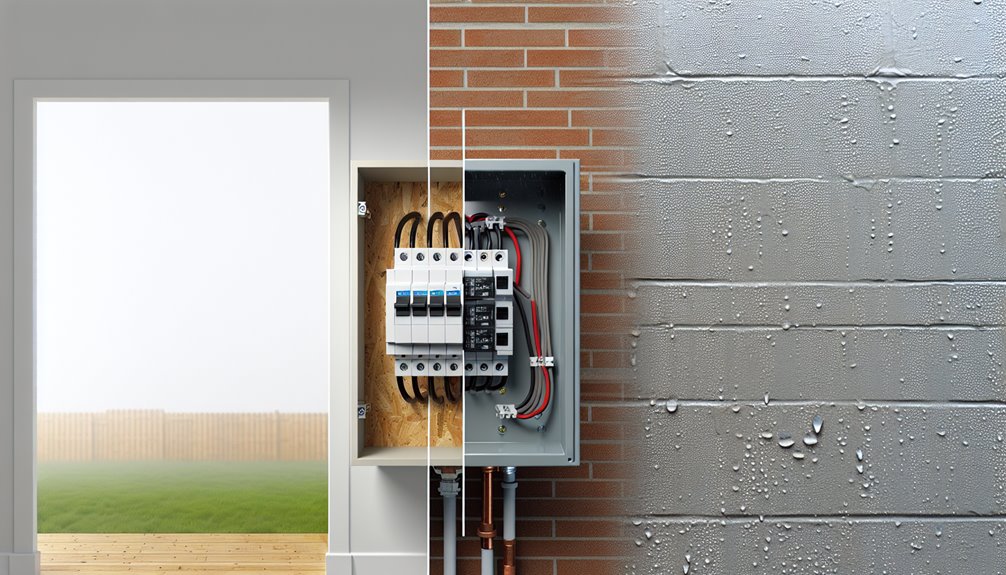

An indoor distribution box is defined by deployment in conditioned spaces such as residential hallways, utility rooms, server rooms, equipment closets, and commercial/industrial control areas, where ambient conditions are dry, clean, and thermally stable.

It assumes low moisture, limited airborne contaminants, and modest temperature swings, enabling an indoor electrical enclosure to prioritize code-compliant clearances, safe touch (IP20–IP54), and organized wire management over weather sealing.

Typical constructions use mild steel with powder coat, aluminum, or polycarbonate/ABS, with flame-retardant ratings and insulation properties suited to interior risks.

Ventilation favors passive louvers or compact fans sized to load dissipation, maintaining accessibility for inspection and lockable control.

The electrical distribution enclosure emphasizes quick install, scalable circuit capacity, and cost efficiency, supporting high unit counts without over-specifying environmental protection.

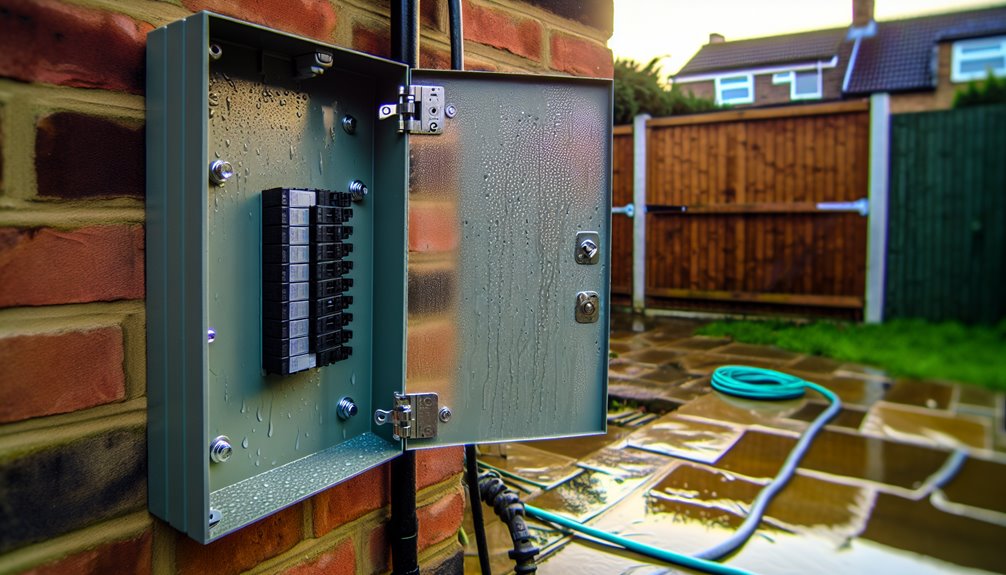

Designed for unconditioned and exposed environments, an outdoor distribution box is specified to maintain electrical safety, reliability, and service continuity under weather, UV radiation, and airborne contaminants. Unlike indoor enclosures, it is engineered as a fully rated outdoor electrical enclosure, incorporating gasketed sealing systems, corrosion-resistant materials, and secure locking mechanisms to prevent ingress, tampering, and premature failure.

Selection should be based on verifiable performance, not nominal claims. Key decision criteria include certified ingress protection (e.g., IP65–IP68), documented mechanical strength, and compliance with applicable electrical and environmental standards. A data-driven specification approach reviews enclosure ratings, third-party test reports, and material certifications to ensure predictable lifecycle performance and regulatory compliance.

| Attribute | Specification Focus |

|---|---|

| Environmental sealing | IP-rated enclosure (IP65–IP68) supported by third-party test reports |

| Corrosion resistance | Stainless steel, coated steel, or UV-stabilised polymers validated by ASTM B117 |

| UV durability | Materials and additives tested to ISO 4892 |

| Structural strength | IK impact rating with documented wind and ice load analysis |

| Security | Lockable hardware, tamper-evident features, audit-ready identification and labelling |

An outdoor distribution box prioritises measurable resilience, controlled risk, and long-term reliability, ensuring safe power distribution in environments where exposure—not load—is the dominant design constraint.

Selecting between indoor and outdoor distribution boxes hinges on environmental protection level, with IP/NEMA targets ranging from IP20/NEMA 12 indoors to IP65–IP68/NEMA 3RX outdoors.

Material and construction shift accordingly—mild steel or ABS/polycarbonate for indoor use versus stainless steel, FRP, or coated steel with gasketed seams and drip edges outside—while mounting and adjustability favor adjustable-depth interiors and fixed, sealed exterior installations.

Security and access control escalate outdoors via lockable latches, tamper-proof hardware, and audit-ready access, compared to basic screw or latch closures indoors.

While indoor and outdoor distribution boxes share the core role of safeguarding live components, their environmental protection levels diverge sharply by standards and exposure. Indoors, a power distribution enclosure primarily mitigates dust ingress, incidental contact, and moderate humidity, prioritizing fire resistance and insulation over weather hardening.

Outdoors, an industrial distribution box must address rain, driven spray, UV, salt fog, freeze–thaw cycling, windborne debris, and broader thermal swings, demanding reinforced seals, corrosion-resistant materials, and mechanical robustness.

Material selection reflects these risks: indoor units commonly use coated mild steel or polycarbonate; outdoor units employ stainless steel, aluminum alloys, or fiberglass-reinforced polyester with UV-stable finishes.

Construction practices also differ—outdoor designs add drip edges, compression gaskets, secure latching, drainage/condensation control, and mounting isolation to maintain long-term protection performance.

Although both systems aim to prevent ingress and accidental contact, indoor and outdoor distribution boxes diverge markedly in expected IP and NEMA performance targets.

For controlled interiors, stakeholders typically specify IP20–IP40, where finger-safe and basic dust resistance suffice, or IP54 for light particulate exposure. NEMA Type 1 or 12 commonly aligns with these environments, balancing access and protection.

Outdoor deployments demand sealed performance: IP65–IP66 for wind-driven rain and washdown, escalating to IP67–IP68 where temporary or continuous immersion is credible.

Corresponding NEMA expectations are Type 3/3R for weather resistance, Type 4/4X for watertightness and corrosion resistance, and Type 6/6P when submersion risks exist.

Selection should map to test-method equivalence, not label parity; verify dust/water ingress tests, hose-down pressures, and corrosion endurance against documented use-case hazards.

Material choice and enclosure construction dictate survivability, compliance, and lifecycle cost.

Indoor distribution boxes commonly use painted mild steel or polycarbonate/ABS blends, optimized for IP20–IP54 environments with limited corrosive agents.

Outdoor boxes prioritize stainless steel (304/316), powder‑coated aluminum, or fiberglass‑reinforced polyester (FRP) to resist UV, chloride, and moisture; gaskets (closed‑cell EPDM or silicone) and formed drip edges maintain IP65–IP66 performance over service life.

Mechanical construction drives integrity: continuous welds or formed seams, captive hardware, and reinforced hinge/hasp systems preserve door compression under wind load.

Fastener metallurgy must match the enclosure to prevent galvanic corrosion. Transparent windows require UV‑stabilized polycarbonate; metals may need passivation or marine‑grade coatings.

Flame ratings (UL94 V), impact resistance (IK08–IK10), and salt‑spray validation (per ASTM B117) provide quantifiable durability thresholds.

Mounting must match the enclosure design and environment. Indoor distribution boxes typically use adjustable depth frames to accommodate unknown wall finishes, allowing ±10–15 mm setback via captive screws or indexed rails. Outdoor enclosures rely on fixed brackets or backplates to preserve gasket compression and maintain IP/NEMA integrity, using stainless or corrosion-resistant fasteners with defined torque.

Relevant standards include NEC 314, UL 50 / 50E, IEC 62208, and NEMA 3R/4/4X. Outdoor mounting must account for wind and vibration loads; indoor layouts prioritise cable density and service access.

| Parameter | Indoor | Outdoor |

|---|---|---|

| Mounting surface | Masonry/poles | Masonry / poles |

| Adjustability | ±10–15 mm | Fixed |

| Fasteners | Zinc-plated | Stainless A2/A4 |

| Gasket impact | Low | Critical |

| Typical ratings | UL 50E | IP65+, NEMA 4/4X |

Because enclosure location dictates threat profiles, security and access control requirements diverge sharply between indoor and outdoor distribution boxes.

Indoors, risks center on unauthorized staff access and incidental contact. Controls typically use lockable doors with keyed or tool-operated latches, IP20–IP54 ingress ratings, and compliance with NFPA 70/NEC working-clearance rules. Badge-based access logging and tamper-evident seals support auditability.

Outdoors, exposure to the public and vandalism elevate requirements. Specifiers favor NEMA 3/4 or IP65+ housings with reinforced hinges, concealed fasteners, pry-resistant cams, and padlock hasps meeting IEC 60068 mechanical tests.

Utilities often require multi-point locking, cylinder standardization, and SCADA-integrated door switches for real-time alarms.

Both contexts benefit from tiered permissions, documented key management, and clear labeling to IEC/ISO symbology to minimize human error.

Security, materials, and thermal design directly affect the total cost of ownership. Higher-spec locks, sensors, and reinforced hardware increase upfront cost but reduce vandalism, unplanned outages, and emergency service calls over time.

Over a 5–10 year lifecycle, performance depends on correct environment classification (IP/NEMA), corrosion resistance, and heat management. Indoor enclosures (NEMA 1, IP20–IP40) minimise material and maintenance costs in controlled spaces. Outdoor enclosures (NEMA 3R/4/4X, IP65–IP68) justify higher CapEx by preventing ingress, corrosion failures, and repeat site visits.

The thermal strategy also influences operating cost. Sun exposure and temperature differential determine whether passive ventilation, fan/filter units, or heat exchangers are required. Integrated monitoring—such as door switches or moisture sensors—reduces MTTR and supports condition-based maintenance.

| Cost Driver | Lifecycle Impact |

|---|---|

| Corrosion | Accelerated enclosure failure |

| Unplanned outages | Service disruption and downtime |

| Emergency call-outs | High reactive maintenance cost |

| Over-specification | Unnecessary CapEx |

Although both systems quantify environmental protection, IP and NEMA ratings translate to practical choices about dust, touch safety, and water exposure.

Indoors, IP20 prevents finger contact with live parts and tolerates benign dust; IP42 adds limited vertical/angled drip resistance—sufficient for conditioned spaces, server rooms, and panels away from washdown.

Outdoors, rain, blown dust, and hose-directed water drive higher ratings: IP65/66 block dust ingress and resist water jets; NEMA 3R resists rain and ice; NEMA 4X adds hose-down and corrosion resistance for coastal or chemically aggressive sites.

Over-specifying wastes budget: using IP66/NEMA 4X inside dry offices adds no measurable reliability benefit.

Conversely, under-specifying risks moisture-driven failures.

Select the minimum rating that meets dust, touch, and water threats verified by site conditions.

Material choice and construction quality directly affect enclosure durability, compliance, and lifecycle cost. Indoor enclosures can prioritise weight, finish, and ease of installation, while outdoor enclosures must withstand corrosion, UV exposure, and mechanical stress.

Material selection depends on environment and performance targets:

| Material | Key Advantages |

|---|---|

| Stainless steel | Maximum corrosion resistance; long outdoor service life |

| Aluminum | Lightweight; good thermal performance |

| Polycarbonate | Non-conductive; UV-stable options available |

Construction details are equally critical. High-quality powder coatings (e.g. TGIC polyester) support C4–C5 corrosion classes, while continuous gaskets, welded seams, and formed drip edges improve ingress protection and structural rigidity. Plastic enclosures are typically suited to IP20–IP54 indoor use, while metal enclosures dominate IP65–IP68 outdoor applications. Always verify material thickness, fastener specifications, and hinge cycle ratings to ensure long-term reliability.

With base materials and construction defined, accessory selection should align with quantified environmental risks and code requirements.

For ingress, gasket profiles and compression latches should be matched to target IP/NEMA ratings; validate via third‑party test data. Grounding provisions—bonding studs, copper busbars, and listed jumpers—must provide sub-0.1 Ω continuity per NEC/IEC guidance.

Surge protection should reflect site exposure: Type 1/2 SPDs at service or feeder points, with UL 1449 ratings sized to fault current and MCOV.

Thermal control depends on load and ambient deltas: specify filtered fans for low dust, heaters with hygrostats to prevent condensation, and closed-loop coolers where particulate or humidity is high.

For security, choose keyed or padlockable handles with tamper switches tied to alarms/SCADA. Add insulation to limit solar gain and prevent internal dew.

In controlled environments, indoor distribution boxes act as central points for circuit protection, load management, and system organisation. They are widely used in residential, commercial, and industrial interiors where exposure to weather, moisture, and contaminants is minimal. Installations typically comply with NEC/NFPA 70, IEC 61439, and indoor-rated UL/NEMA (Type 1, Type 12) or IP20–IP54 requirements.

In residential and commercial buildings, indoor boxes distribute lighting, socket, and small equipment circuits, often integrating AFCI/GFCI protection, metering, and surge devices. Industrial control rooms and OEM panels use them to house MCCBs, MCBs, contactors, PLC I/O, and terminal blocks, supporting selective coordination, safe isolation, and lockout/tagout procedures. Data and utility rooms emphasise circuit segregation, clear labelling, arc-flash boundaries, and maintenance access to ensure operational safety and serviceability.

| Application Zone | Primary Function |

|---|---|

| Residential / Commercial | Branch circuit distribution and protection |

| Industrial Control Rooms | Motor control and system coordination |

| Data / Utility Rooms | Circuit segregation and safety management |

| OEM Panels | Custom control and I/O integration |

Outdoor distribution boxes serve as weather-rated nodes for power and controls wherever circuits exit conditioned spaces, spanning building exteriors, public infrastructure, renewable energy assets, and temporary/exposed worksites.

On facades and roofs, they consolidate branch circuits for lighting, signage, EVSE, snow-melt, and motor loads, with NEMA 3R/4 or IP65+ protection and corrosion-resistant hardware.

In utilities and transport, cabinets on poles, pedestals, and waysides support feeders, metering, traffic control, CCTV, and communications, integrating surge protection and lockable isolation.

For solar PV and renewables, they house DC combiners, disconnects, overcurrent devices, and monitoring, with UV-stable materials and ingress management.

On construction sites and events, ruggedized, portable units provide GFCI-protected receptacles, load segmentation, and clear labeling to maintain uptime and safety under variable conditions.

Too often, specifications miss critical distinctions between environments and duty cycles, leading to four recurring errors: selecting indoor-rated boxes for outdoor exposure, overpaying for unnecessary NEMA/IP extremes, neglecting ventilation/thermal management, and underestimating capacity for future circuits and devices.

First, indoor boxes lack corrosion resistance, UV stability, and gasketing; specifying them outdoors risks water ingress and early failure. Match environment to NEMA 3/3R/4 or IP65+ as required, not assumed.

Second, overspecifying IP67/68 or NEMA 4X where IP54 or NEMA 12 suffices inflates cost without reliability gains; verify actual dust/water exposures.

Third, ignoring heat load from sun and electronics elevates MTBF risk; calculate watts loss, apply derating, and include vents, fans, or heat exchangers.

Finally, misjudged growth constrains circuits; size busbars, DIN space, and breaker count with 250% spare capacity.

Local codes dictate submittal content, review sequencing, and inspection milestones, directly affecting permit duration. Jurisdictions with strict plan-check cycles, specialty reviews, and mandated NEMA/IP compliance add iterations. Early compliance mapping, pre-application meetings, and approved product listings materially compress timelines and inspection frequency.

Required documentation typically includes purchase invoice, serial/model numbers, installation records, commissioning reports, maintenance logs, photos/videos of failure, environmental/IP/NEMA compliance evidence, load and wiring diagrams, fault descriptions, RMA authorization, and adherence to manufacturer’s claim form, timelines, and exclusion clauses.

Yes, but only under manufacturer guidance. Repainting must not alter IP/NEMA ratings, enclosure grounding, thermal properties, flame spread, or labels. Use approved coatings, surface prep, and cure schedules; document process. Unauthorized paint on gaskets/hinges/labels typically voids certification.

Best practice is 25–30% spare breaker space, ~20% busbar headroom, and reserved DIN rail and cable routing space. Capacity should be validated with load calculations and NEC/IEC clearance rules.

Insurers require enclosures to meet listed standards (UL/NRTL, NEMA/IP), correct location class (NEC/IECEx), fire ratings, and clearances. Underwriters assess flood/impact risks, maintenance logs, and documentation. Noncompliance elevates premiums, exclusions, or denial; compliant placement lowers risk scores and supports business interruption and liability coverage.

Selecting the right distribution box is fundamentally an environmental and risk-based decision. Indoor enclosures (IP20–IP40) are suited to controlled conditions where access, aesthetics, and cost efficiency matter most. Outdoor enclosures (IP65–IP68, NEMA 3R/4/4X/6P) are engineered to withstand moisture, dust, UV exposure, and mechanical stress, justifying higher specifications where uptime is critical.

Material choice, sealing integrity, locking mechanisms, thermal capacity, and compliance with applicable standards should be aligned with site conditions and operational expectations. Planning spare capacity for future circuits, proper cable management, and surge protection at the specification stage prevents disruptive and costly retrofits later.

For projects where specification accuracy, certification, and long-term reliability matter, Conya supports engineers and project teams with enclosure solutions designed around real installation environments—backed by tested materials, verified protection ratings, and application-focused engineering support.

If you’re defining requirements or validating an enclosure selection, engaging early helps ensure the solution fits both today’s conditions and tomorrow’s demands.