An electrical distribution box is a standardized enclosure that accepts incoming power from a feeder and allocates it to multiple branch circuits under defined protective and isolation requirements. It typically integrates overcurrent protection, residual-current protection where mandated, and provisions for safe switching and fault containment. Selection and layout are constrained by load characteristics, short-circuit ratings, earthing arrangements, and enclosure ingress protection—constraints that quickly determine what is acceptable and what is not.

Although terminology varies by region and standard, an electrical distribution box is a protected enclosure that receives power from an upstream supply (service entrance or feeder) and subdivides it through busbars and protective devices—such as circuit breakers, fuses, RCD/RCCBs, and surge protection—into multiple downstream branch circuits for loads (lighting, receptacles, appliances, and equipment), thereby providing localized isolation and overcurrent/leakage protection.

In the distribution hierarchy, it is downstream of the service disconnect or switchboard and upstream of final circuits, and may also appear as a sub-panel feeding a zone. A distribution board (panelboard) is typically a standardized branch-circuit panel; a switchboard is higher-capacity, often sectionalized, for service-level distribution.

The electrical panel box term is commonly used for the same enclosure class, with ratings defined by applicable IEC/UL and ingress requirements.

An electrical distribution box serves as the control and protection centre of a power distribution system. Its role goes far beyond simply routing electricity from a supply source to end circuits. In practical terms, it ensures that power is distributed safely, reliably, and in a controlled manner across different loads and applications.

At its core, the distribution box performs the following key functions:

The distribution box receives electrical power from the main supply and divides it into multiple outgoing circuits. Each circuit is dedicated to a specific load or area, allowing electricity to be delivered efficiently without overloading a single line. This structured distribution is essential for maintaining system stability in residential, commercial, and industrial installations.

One of the most critical functions is protecting downstream circuits and connected equipment. Built-in protective devices such as circuit breakers, fuses, or residual current devices automatically interrupt the power supply in the event of overloads, short circuits, or earth faults. This helps prevent equipment damage, fire hazards, and electrical accidents.

Distribution boxes allow individual circuits to be safely isolated without shutting down the entire system. This makes maintenance, troubleshooting, and system upgrades far safer and more manageable. Operators can disconnect specific circuits for inspection or repair while keeping other parts of the installation operational.

By separating loads into multiple circuits, the distribution box helps balance electrical demand across phases and feeders. Proper load distribution reduces voltage drops, minimises overheating, and improves overall system efficiency—especially important in installations with fluctuating or high-power loads.

The enclosure itself plays an important safety role. By housing live components inside a protected enclosure, the distribution box reduces the risk of accidental contact with energized parts. In the event of a fault, it also helps contain arcs, heat, and debris, supporting compliance with electrical safety standards and installation codes.

Together, these functions make the electrical distribution box a critical safety and reliability component rather than a passive enclosure. Its correct selection, configuration, and installation directly influence the performance and lifespan of the entire electrical system.

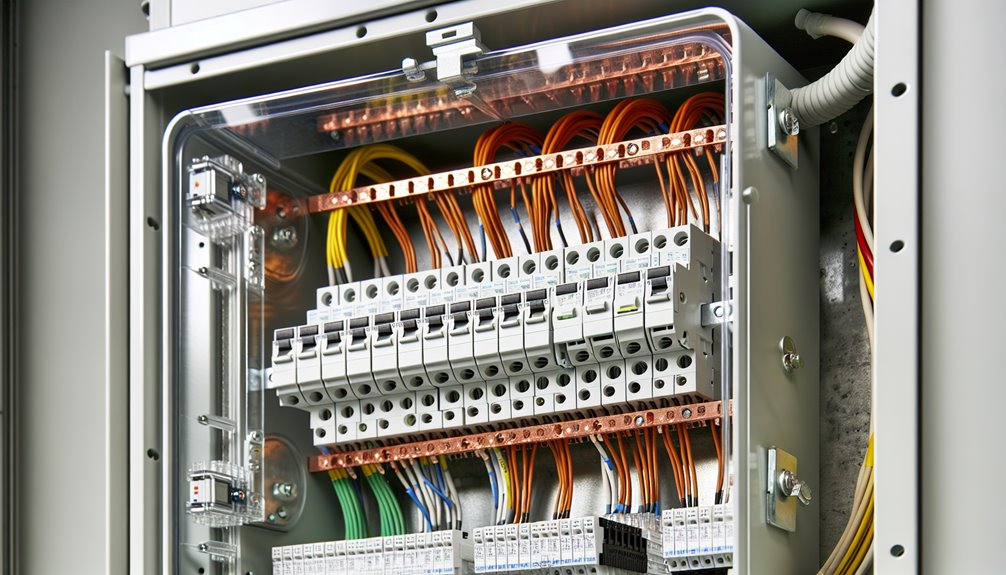

Inside an electrical distribution box, the component set functions as an integrated protection-and-control assembly that must maintain defined current paths, fault-clearing performance, and safe segregation under applicable wiring and enclosure standards.

Circuit breakers and fuses provide coordinated overcurrent interruption, while RCD/RCCB/RCBO devices enforce residual-current protection for personnel and fire risk mitigation.

SPDs clamp transient overvoltages to prescribed protection levels.

Busbars and terminals establish low-impedance distribution and verified torque retention for conductor terminations.

Voltage, current, and energy meters enable controlled loading and documentation.

Grounding and neutral systems maintain reference potential, fault return paths, and separation rules.

The enclosure, insulation, and internal layout govern creepage/clearance, heat dissipation, and ingress protection; an outdoor distribution box or ip65 distribution box must preserve these functions throughout service.

Each db box must support safe isolation and labeling.

Types of electrical distribution boxes are typically classified by function and by application to align enclosure selection with system architecture and applicable electrical codes.

Functional categories include main breaker panels, main lug panels, sub-panels, and transfer-switch configurations, each defining the point of isolation, protection coordination, and source selection within the distribution scheme.

Application-based categories distinguish residential, commercial, industrial, and weatherproof/outdoor enclosures, reflecting differences in load profile, circuit count, environmental rating, and required safety features such as RCD/RCCB and surge protection.

Functional classification provides a practical framework for specifying electrical distribution boxes within a power distribution system, aligning enclosure selection with protection, switching, and continuity requirements.

Selection is driven by required isolation points, fault-energy limitation, and source-transfer behavior, ensuring that upstream and downstream devices coordinate under abnormal conditions.

Functional types typically include: main distribution boxes, sub-distribution boxes, transfer switch/ATS boxes, and fuse distribution boxes, each defined by how it controls and protects feeders and outgoing circuits.

A fuse distribution box emphasizes current-limiting protection and selective coordination where specified.

Application context acts as the primary determinant for electrical distribution box (DB) design, because enclosure ratings, fault levels, circuit density, and monitoring requirements must be matched to the installation environment and load profile to maintain compliance and coordination.

Residential distribution boxes prioritize compact form factors, standardized branch protection, and straightforward isolation aligned to typical lighting and receptacle circuits.

Commercial distribution boxes scale circuit count, segregation, and metering to support mixed loads, tenant demarcation, and maintainable shutdown procedures.

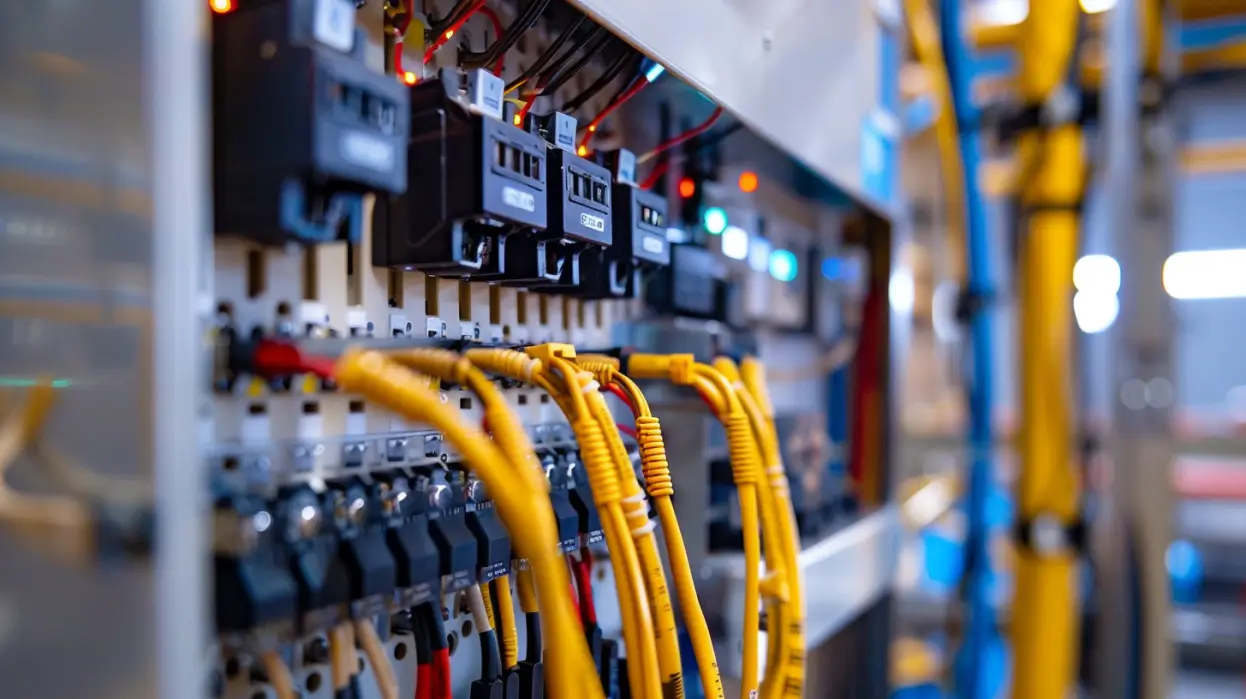

Industrial distribution boxes address higher prospective short-circuit currents, motor starting duties, and selective coordination, often requiring robust busbar systems and enhanced thermal management.

Renewable energy/solar distribution boxes integrate DC/AC segregation, surge protection, and disconnecting means for inverter interfaces, with weatherproofing where rooftop or outdoor mounting drives ingress requirements and service access.

Although the internal protective devices define a distribution box’s electrical performance, the enclosure material and sealing specification largely determine whether that performance can be maintained under heat, impact, corrosion, and environmental ingress.

Material selection typically balances mechanical robustness, dielectric behavior, and lifecycle exposure. Metal enclosures provide high impact resistance and inherent shielding, but require corrosion control for outdoor duty.

Plastic enclosures reduce weight and resist corrosion, but must be specified for flame retardancy and UV stability.

Protection against dust and water is managed through ingress ratings, with common baselines defined as IP54 for limited splash/dust, IP65 for water-jet exposure, and IP67 for temporary immersion.

Control points are consequently:

When selecting an electrical distribution box, the decision is typically anchored to quantified load capacity and the required circuit count, then validated against the site’s voltage level and system type (e.g., single‑phase vs. three‑phase).

The enclosure and internal clearances should then be matched to the installation environment, separating indoor dry locations from outdoor or washdown areas that demand sealed, corrosion‑resistant ratings.

Selection should be constrained by compliance requirements: IEC or UL listing as applicable, plus local code mandates for overcurrent protection coordination, leakage protection provision, and labeling.

For controlled lifecycle management, the box should include spare ways, neutral/ground bar capacity, and busbar headroom to accommodate future circuits, monitoring modules, or surge protective devices without requiring a full panel replacement later.

Most distribution box installation failures trace back to inadequate pre‑installation planning and verification rather than component defects.

Planning should confirm prospective fault levels, circuit schedules, IP rating, and coordination of protective devices with upstream isolation. Mounting must meet manufacturer's torque data, enclosure orientation, and code-required clearance for access, heat dissipation, and safe isolation.

Professional installation is required where local regulations mandate licensed work, or where fault energy, multi-source supplies, or critical loads elevate risk.

With installation checks completed (fault level verification, device coordination, clearance, and pre‑energisation testing), the application context determines how an electrical distribution box is specified and configured in relation to circuit count, segregation, monitoring, and enclosure rating.

In residential buildings, compact consumer units support lighting and socket circuits, typically integrating RCD/RCCB protection and SPDs per local code.

Commercial facilities use distribution boards with higher circuit density, provision for sub‑panels, and metering to control tenant and HVAC loads.

Industrial plants apply robust panels for heavy machinery feeders, selective coordination, and clear functional segregation of power and control circuits.

Data centres and infrastructure emphasise redundancy, transfer switching, and branch‑circuit monitoring for uptime and energy reporting.

Solar and renewable energy systems require AC/DC segregation, inverter interconnection, and environmental enclosures aligned to site conditions.

Although an electrical distribution box is designed to segment loads and clear faults predictably, field failures commonly arise from preventable conditions—overloading that drives conductor and device heating beyond rated temperature rise, ineffective grounding/bonding that compromises fault‑clearing and touch‑voltage limits, and moisture ingress that degrades insulation resistance and promotes tracking and corrosion.

So a standards‑aligned safety approach relies on correct protective‑device selection/coordination, enclosure environmental ratings, verified earthing continuity, and defined inspection and maintenance intervals to maintain compliance and reliable operation.

Controls typically prioritize:

Electrical distribution boxes should be inspected at least annually and serviced immediately after faults, modifications, or abnormal load events. Preventive checks should verify breakers, RCDs, busbars, terminals, sealing, thermal condition, and compliance with applicable codes.

A distribution box typically lasts 20 to 30 years under normal conditions. Service life depends on load profile, ambient temperature, enclosure integrity, component wear, and code-compliant installation. Scheduled annual inspections and corrective maintenance are required to sustain reliability and safety.

Yes, an existing box can be upgraded—like adding eyes to a system—for smart monitoring, if enclosure space, busbar ratings, and wiring permit. It requires certified smart breakers/SPDs/meters, code compliance, and qualified installation and verification.

Compliance depends on jurisdiction: IEC 61439 (assemblies), IEC 60529 (IP), IEC 61008/61009 (RCD), IEC 61643 (SPD), UL 67/508A or CSA C22.2, plus local wiring codes and utility requirements. Verify accredited labeling.

Label each circuit with a consistent scheme—like a well-tuned metronome—using panel schedules, unique alphanumeric IDs, load descriptions, and destination zones. Match breakers to drawings, update as-built records, and reserve spare IDs for controlled future expansion.

An electrical distribution box remains the linchpin of safe, standards-aligned power distribution, providing controlled segmentation, protection coordination, and local isolation across downstream circuits. Correct selection and installation depend on load analysis, fault levels, environmental ratings (IP/NEMA), enclosure materials, and compliant device integration (breakers, RCDs/RCBOs, busbars, earthing). When maintained and inspected, it mitigates overheating, nuisance tripping, and insulation failures. In practice, it keeps the system on an even keel.

Conya supports a wide range of electrical distribution boxes and enclosures, with options for customization, material selection, IP protection levels, and compliance with international standards.

For projects that require clarity rather than guesswork, Conya’s technical team can help evaluate requirements and recommend solutions that align with real operating conditions.

Feel free to reach out when you need practical guidance — not just products.